7. Accelerating innovation to meet global challenges: The role of engineering biology

Life science innovation will be critical for addressing the major challenges of our time, from pandemics, through climate change, to transitioning to sustainable production systems. Synthetic biology, also known as “engineering biology”, aims to harness biologic processes to act as a platform technology across a wide range of key economic sectors. What is required to create the enabling conditions for the field, and how might the field contribute solutions to the complex problems we face? This chapter locates the challenges of the pandemic and sustainability, writ large within the landscape of key advantages and advances in engineering biology. Beginning with the “biofoundry”, these approaches to engineering practice promise to open up new opportunities for manufacturing. These span a wide range of sectors and products, whether new materials, greener chemicals or – most pertinent for this particular moment – diagnostics and vaccines.

The COVID-19 crisis underlines the need to promote a mission of health resilience, both on shorter and longer time horizons, requiring robust investment in health science and technology. Promising new technologies like engineering biology deserve consideration as a possible means towards the achievement of health resilience as a longer-term mission. The field’s development could be driven through mission-oriented policies in order to assure alignment of technology development and the goal of health resilience.

Governments could establish and support pre-competitive infrastructure and collaborative platforms, such as networked biofoundries and research consortia, by ensuring long-term and stable funding. Such research and translational infrastructures could de-risk private investment and accelerate commercialisation.

Collaborative platforms, built around biofoundries and other emerging technologies, can help deepen the engagement of broader society with emerging technologies. In that context, the societal engagement of collaborative platforms with actors outside its innovation activities is becoming increasingly important. Maintaining levels of public involvement and engagement over the platform lifetime can build the mutual trust and social contract that needs to support the enterprise.

Governments should encourage the development of multidisciplinary environments and transdisciplinary skills to promote convergence. Engineering biology extends beyond traditional discipline boundaries, drawing from engineering, biology, data science and physical sciences. Multidisciplinary environments are key to its success, and rely on people who can communicate across disciplines.

The race is on to limit the effects of climate change by all available means. With around 70 000 derived products (Cayuela Valencia, 2013[1]), chemistry is the largest commercial enterprise on the planet, but is responsible for very large greenhouse gas (GHG) emissions. Moreover, the chemical and petrochemical industry is the largest contributor to industrial (fossil) energy demand worldwide (Griffin, Hammond and Norman, 2018[2]). The appeal of engineering biology lies in the fact that biological reactions require renewable carbon resources (e.g. sugarcane) as feedstocks and reactions occur at low temperatures and ambient pressures, requiring few energy inputs, in direct contrast to the incumbent fossil economy.

Engineering (or “synthetic”) biology as a discipline of basic biology research started early in the 21st century (Cameron, Bashor and Collins, 2014[3]), and its applications to various branches of manufacturing were clear from the outset. The terms “engineering biology” and “synthetic biology” are now considered synonymous, even though practitioners see some nuances. If there is a difference, it is that engineering biology is an attempt to turn biotechnology into a discipline more reminiscent of engineering than biology, i.e. more sharply focused on industrial production.

The arrival of the COVID-19 pandemic has highlighted problems associated with society’s readiness to deal with emerging viruses and pandemics, underscoring the importance of new biotechnology approaches. Indeed, COVID-19 may represent an opportunity for engineering biology to exert a tangible economic and social impact on health.

This chapter first examines the recent emergence of the new technology platform in engineering biology called the “biofoundry” – a promising new vehicle to speed up the development of useful constructs. The chapter then turns to the possible application of engineering biology and the biofoundry to vaccines and diagnostics, which are critically important in the context of the COVID-19 pandemic. While engineering biology has struggled to make an impact on liquid fuels and commodity chemicals (where the largest gains in GHG emissions reductions are to be made), there is hope that it could play a significant role in other fields. Third, the discussion reviews emerging trends in the development of bio-based products, from spider silk to encoding information using DNA. Finally, it sets out a suite of policy considerations that would prove useful for developing road maps and other policy interventions related to engineering biology.

The field of engineering biology has advanced rapidly in recent years (Opgenorth et al., 2019[4]), to the point where a Design-Build-Test-Learn cycle (DBTL) has emerged. This has been made possible by robotics and machine learning that can integrate and enhance human intervention (Figure 7.1). This cycle is encapsulated in the biofoundry, where many candidate molecules can be run iteratively through the DBTL cycle to quickly obtain an optimised candidate.

The technical challenges are many, but one of the greatest challenges for engineering biology is scale-up. The reasons lie with the technical details of biology: the feedstocks have to be dilute; the bioprocess is slow; and the products are also dilute, requiring considerable effort to concentrate and purify (Wu and Maravelias, 2019[5]). In chemistry, by contrast, the opposite is true: feedstocks are concentrated; reactions are fast; and products are concentrated, requiring less effort and cost to purify. For these reasons, biology will continue to struggle to compete with chemistry, particularly as the chemical industry is also rising to the challenge of sustainability (Horváth, 2018[6]).

Biofoundries are highly automated facilities that allow the co-ordinated use of laboratory robots. They are based on information infrastructures that enable programming robots and other equipment within the biofoundry to follow detailed, complex workflows (Chao et al., 2017[7]). Bio-designers are able to produce genetic constructs which, when placed in a cell (or chassis, such as Escherichia coli, or E. coli), act as an instruction set for the cell to produce other molecules that it would not naturally produce.

The hope is that biofoundries will greatly reduce the time from idea to product, and improve the reliability and reproducibility that have been lacking until now in biotechnology. One of the drivers of engineering biology is the aim to increase reproducibility so as to enable the quantitative precision required for modern manufacturing. Standards, automation and machine learning are key to the success of this approach, which is applicable to both research and industrial production (Box 7.1).

Biofoundries rely on the ability to modularise gene constructs and then study the behaviour of the construct using a technique called “characterisation”. Typically, a construct is characterised over several days, systematically following a workflow protocol. The workflow approach is designed to greatly increase reliability and reproducibility, with machine learning being key to speeding up the cycle. When a gene construct has been fully characterised, the process should be geographically transferable, thus building the link to distributed manufacturing. Many industrial bioprocesses have never had the biocatalyst optimised in any way to deal with the conditions of fermentation or maximise productivity. Thus, the biofoundry may represent a “missing link” in industrial bioprocessing.

The combination of bio-design tools and biofoundries is producing the digital biology that could revolutionise the manufacture of many desirable bio-based products. A feature of the biofoundry approach consistent with modern manufacturing is that the design site (the biofoundry) can be totally separated from the manufacturing site (typically the biorefinery).

The biofoundry as a public-private partnership

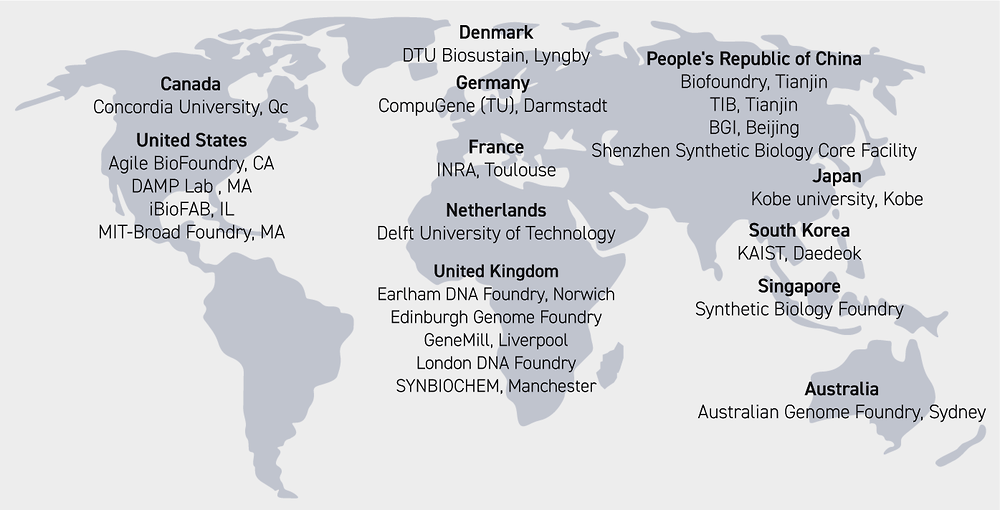

Biofoundries exist, albeit in small numbers (Figure 7.2). As with other areas of bio-based production, the private sector may not be willing to take the risk of building expensive infrastructure in the absence of supportive policy or a market in which the products can compete on price. To advance the diffusion of this technology, many biofoundries have been built using public support.

Ideally, private-sector enterprises can interact with public facilities to advance their R&D capabilities, creating true public-private partnerships. When industry sectors come together to identify high-risk, capital-intensive fundamental research questions aligned with government priorities, high-impact partnerships can result, and major barriers preventing bioeconomy advances can be overcome. There exist relatively few working models for such partnerships, but the Agile BioFoundry (ABF) in the United States is an interesting example (Box 7.2). The ABF acts as a nucleus for developing industrial and innovation ecosystems for the bioeconomy. Some of the best-known synthetic biology companies in the United States have worked on projects with the ABF (Philp and Winickoff, 2019[8]). A biofoundry like the ABF is able to perform this function because it aligns perfectly with a central tenet of distributed manufacturing, namely, that much of the physical supply chain is replaced by digital information. Such infrastructure is expected to enable smaller (and even micro-scale) manufacturing much closer to the end user (Srai et al., 2016[9]).

The ABF is a facility of the U.S. Department of Energy (DOE). This public infrastructure investment totalling USD 20 million per year is designed to increase US industrial competitiveness while creating opportunities for private-sector growth and jobs. Any legal entity within the United States or abroad is eligible to use the platform, subject to DOE review/approval and the terms specified in the two primary contractual mechanisms governing the performed work: Collaborative Research and Development Agreements (CRADAs) and the Strategic Partnership Program (SPP).1The ABF operates under full cost-recovery accounting practices, meaning that collaborators pay for labour and laboratory consumables.

Interaction is strongly influenced by intellectual property (IP) arrangements, which are governed by the contracting mechanism (CRADA vs. SPP). For SPP projects, which are typically smaller in scope than CRADAs, a US-owned partner (such as a company) using non-federal funding to pay for the project can elect title to all project inventions. For CRADA projects, IP ownership follows inventorship. If DOE funding supports any of the work (i.e. “for DOE lab inventions”), the collaborator can choose between a six-month no-cost option on a royalty-bearing exclusive licence in a field of use, or an 18-month no-cost option on a royalty-bearing non-exclusive licence in all fields of use. The CRADA is non-negotiable. If no DOE funds are used for the project, the CRADA is negotiable, and the collaborator is offered the standard six-month option on an exclusive licence in a field of use.

It is possible, as part of CRADA projects, for companies to embed their employees within the ABF as they pursue the collaborative work. Non-governmental organisations and foundations may help co-ordinate activities (e.g. through the Global Biofoundry Alliance (Hillson et al., 2019[10])) and set the standards practised at the ABF (e.g. the Synthetic Biology Open Language).2

← 1. https://agilebiofoundry.org/work-with-us/ (accessed 14 September 2020).

← 2. https://sbolstandard.org/ (accessed 14 September 2020).

Vaccines

Despite several important outbreaks of viral disease during the first decades of the 21st century, the vaccine industry is being challenged. An important study (National Academies of Sciences, Engineering, and Medicine, 2020[11]) indicated that the amount spent by the United States on vaccines “appears to be insignificant compared with that spent on other medical and social interventions that may have lesser social benefits.” Fixed costs for traditional vaccine production plants are very high. Even if there exists theoretically no shortage of a particular vaccine, there is every chance that there exists a shortage in the places where it is most needed – i.e. close to the location of disease outbreak. Transportation of vaccines often depends on a very robust cold chain, but many instances of cold-chain temperature failures have been recorded.

Engineering biology could present a useful set of tools in this context. Several COVID-19 vaccines either in current use or in late-stage clinical trials are messenger RNA (mRNA) vaccines, which are amenable to an engineering biology approach. The mRNA is specifically designed to produce the exact antigens required to counteract the target virus. Many prototypes can be designed and built in biofoundries. This approach presents a number of advantages. First, production/manufacture can be achieved directly in the laboratory, cell-free and egg-free. Second, instead of transporting a vaccine over a cold chain that often fails, it is digital information that is transferred to a small production plant close to where the vaccine is actually needed. Third and most importantly, speed is of the essence. (Ulmer, Mansoura and Geall, 2015[12]) described a proof of concept for the production of a self-amplifying mRNA influenza vaccine, from gene synthesis to formulation and release, in 13 days, which they anticipated could be reduced to 5 days.

Various existing non-commercial biofoundries offer an integrated infrastructure, including automated high-throughput equipment to enable prototyping biological testing standards and developing liquid-handling workflows for diagnostic testing of SARS-CoV-2 (Crone et al., 2020[13]). The biofoundry can also be applied to the design of certain vaccine types (Ulmer, Mansoura and Geall, 2015[12]).

Beyond the potential of engineering biology in vaccine design, it is also important to consider its use in design and optimisation of vaccine (and other viral vector) bio-manufacturing processes and cell lines to enhance production. Similarly, engineering biology has myriad applications in design and optimisation of cellular therapeutics, and their parallel manufacturing processes; this becomes important when considering point of care delivery of cell products.

In some sectors – particularly chemistry – replacing the economies-of-scale model is difficult, since great efficiencies have been achieved by centralised, large-scale manufacturing. In pharmaceutical production, however, there exist compelling reasons for the industry to scale down (National Academies of Sciences, Engineering, and Medicine, 2020[11]). An essential enabler is that many pharmaceuticals – especially biopharmaceuticals – do not respond to economies of scale. This is certainly true of vaccines: compared to commodity chemicals, they are high-value, low production-volume products. Simply increasing production volume would not translate into lower costs or prices.

The engineering biology approach also lends itself to the vision of so-called distributed manufacturing1 in small facilities at many locations that might offer a more attractive production model. The combination of remote design facilities like biofoundries and small-scale production plants located as close as possible to the point of care makes sense in a world that needs to act much more urgently when threatened by new disease outbreaks and pandemics. The pharmaceuticals industry is, in fact, looking at ways to downsize: biopharmaceuticals do not respond to economies of scale in the same way that commodity chemicals do.

Distributed manufacturing could help “democratise” the responses to pandemics (National Academies of Sciences, Engineering, and Medicine, 2020[14]) and oppose the spectre of “vaccine nationalism” (Weintraub, Bitton and Rosenberg, 2020[15]). Vaccine manufacturers in developing countries already supply more than half of the vaccines used in developing-country immunisation programmes, so the capabilities exist. Implementing distributed manufacturing is a matter of political will and further diffusion of the relevant technologies.

Diagnostics and medical devices

Beyond vaccines, the biofoundry/distributed manufacturing approach is also applicable to diagnostics and medical devices. The potential of the approach was demonstrated by (Crone et al., 2020[13]), who showed that an automated SARS-CoV-2 clinical diagnostics technical platform designed and developed in a biofoundry could be quickly deployed and scaled.

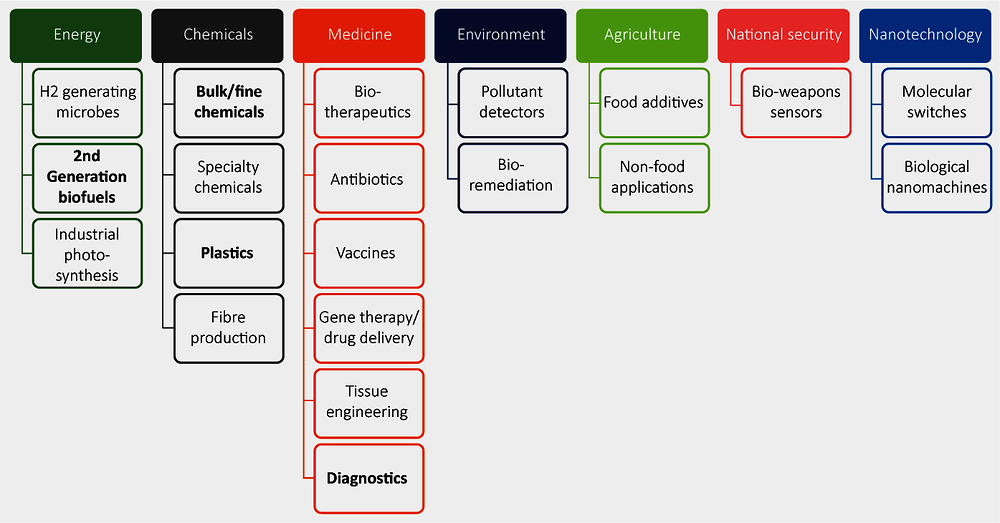

Engineering biology partly owes its appeal to its ability to act as a platform technology across a wide range of the most important economic sectors (Figure 7.3). The need to reduce carbon emissions and fossil-fuel consumption also represents an opportunity for engineering biology to emerge as a service and manufacturing sector: by 2100, more than 95% of chemicals and polymers may need to be derived from renewable resources (Devaney, 2016[16]). Applications for engineering biology even exist in space: the National Aeronautics and Space Administration in the United States, for example, supports engineering biology to reduce the risks associated with space exploration (U.S. Government Accountability Office, 2018[17]). Back on Earth, engineering biology could be used to engineer microbes to produce targeted nutrients for human consumption, while bacteria could be manipulated to produce lightweight construction tools and materials. With this range of applications in mind, engineering biology needs to make the leap from a science-centred discipline to a field of engineering that incorporates modern paradigms of manufacturing.

The shift from biofuels to higher-value bio-based products

Consistent with an alignment on sustainability goals, the earliest commercial scale efforts in engineering biology focused on producing liquid biofuels. Some high-profile initial public offerings targeting this area were launched in 2010-12, especially in the United States. Despite many research successes, these companies were unprepared for the magnitude of the task of bringing a liquid biofuel to sufficient scale to significantly influence the market for fossil fuels (Westfall and Gardner, 2011[18]). Further, there was much criticism about the sustainability of the feedstock used, and their impacts on carbon emissions.

“Second-generation” engineering biology companies have since emerged, targeting higher-value, lower production-volume products (Check Hayden, 2014[19]). The commercialisation of synthetic biology vanillin is one notable recent success. Used in many products, synthetic vanillin is typically produced from petrochemicals or chemically derived from lignin (wood pulp). The Swiss company Evolva created a genetically modified yeast that converts sugars to vanillin. It is the first major synthetic biology food additive to hit supermarkets, and others are in development. Flavours and fragrances can command prices ranging from USD 10 to USD 10 000 per kilogramme, compared with around USD 1 per kilogramme for biofuels.

New materials: Spider silks

The application of engineering biology to the development of new materials is a promising avenue for innovation. Spider silks, the sturdiest known biological materials, are an interesting example. They are stronger than steel and tougher than Kevlar® but also flexible, with a large range of applications. Spider silks are lightweight and virtually invisible to the human immune system, leading to “revolutionary potential” for medicine and industry (Babb et al., 2017[20]). Engineering biologists are interested in spider silks because they can be customised for different materials and applications. Among the newer potential applications of spider silk are microphones in hearing aids and cell phones. The German company AMSilk has entered into an agreement with Airbus to develop structural materials for aircraft using synthetic spider silk, and Adidas has developed a biodegradable shoe using this material. Silk also has high-value applications in cosmetics, and Givaudan has acquired the cosmetics business of AMSilk.

Adipic acid as a petrochemical equivalent

Whereas spider silk represents an entirely new industrial material, many of the products derived from synthetic biology are petrochemical drop-ins, i.e. bio-based, sustainable equivalents of an existing petrochemical. Switching to bio-based alternatives has proven difficult for a variety of reasons, including that many of these petrochemicals are produced very efficiently (although unsustainably, with large GHG emissions). A classic example is adipic acid, one of the most important small molecules in the modern chemicals industry and an intermediate in the production of nylon. Industrial production of adipic acid relies on fossil feedstocks and produces large amounts of nitrous oxide, a GHG that is 300 times more potent than carbon dioxide (CO2). (Suitor, Varzandeh and Wallace, 2020[21]) described the first synthesis of adipic acid from guaiacol, a lignin-derived feedstock, in the biotechnology industry workhorse bacterium E. coli. Lignin is available in large quantities and is recalcitrant to many applications. It is effectively a waste product, and its conversion to adipic acid using synthetic biology keeps it in circulation, contributing both to the bioeconomy and the circular economy.

Green chemistry

Green chemistry and automated chemistry are obvious technologies for convergence with engineering biology. Automated chemistry is also developing rapidly, using the same principles as engineering biology, i.e. robotics, artificial intelligence and machine learning (Coley et al., 2019[22]).

A potential example of chemistry/biology convergence is graphene, which conducts electricity better than copper and will eventually find its way into consumer electronics. Electricity conductance and flexibility mean that graphene has a very wide range of potential applications, from energy-storage devices to lighting and displays, solar panels, tyres, bicycle frames and fashion items (Mertens, 2018[23]). For example, deformable graphene batteries with flexible, foldable, and/or stretchable capabilities are ideal for wearable and portable electronics (Ye et al., 2018[24]), and graphene may be the material of choice for 3D printable batteries. However, the cost of graphene has until now been much higher than mass-market applications can support.

Researchers at the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Australia have created a new method of graphene synthesis, which involves heating cheap and available soybean oil in air until it breaks down into carbon-building units that are essential for the synthesis of graphene (Seo et al., 2017[25]). The CSIRO researchers demonstrated the versatility of the method by using other renewable carbon-containing materials, such as butter. It is conceivable that automated biology could produce the optimum bio-based feedstocks for this conversion, while automated chemistry would create graphene molecules for different applications.

Long-term data storage

By 2040, if all data were stored for instant access, the global data archive would consume 10 to 100 times the expected supply of microchip-grade silicon (Zhirnov et al., 2016[26]). Without radical change, a data crunch may be unavoidable. The storage potential of DNA is shown to vastly exceed the storage potential of all other media. In fact, it is estimated that all the world’s data could be stored in one kilogramme of DNA (Extance, 2016[27]). At first sight, it seems far-fetched to store digital data in DNA, but this technology is already leaving research laboratories: companies such as Twist Bioscience are seriously engaging with DNA storage for research and commercial purposes.2 Although currently expensive, storage costs are likely to drop as the customer base increases.

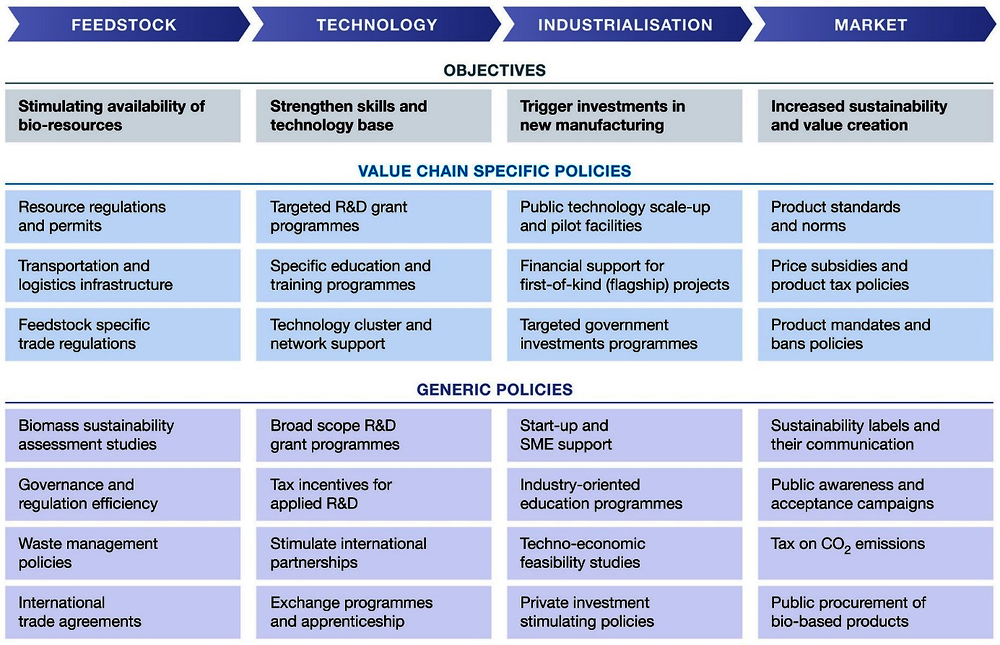

Several governments, notably the People’s Republic of China, the United Kingdom and the United States, have invested heavily in engineering biology. To sustain such commitments, the engineering biology community needs to provide more examples of success in transforming ideas into commercial products and services (OECD, 2014[28]). Creating the enabling conditions for the development of engineering biology would require a range of policy interventions addressing specific issues along bio-based value chains, as well as more generic framework conditions. Among the most critical policy interventions in this area are those discussed in Figure 7.4, notably: developing a pre-competitive infrastructure and innovation ecosystem for engineering biology, addressing systemic business risk in bio-based value chains, ensuring the sustainability of feedstocks and supply chains, enhancing policy co-ordination, promoting public acceptance of these technologies and preventing potential digital-security risks.

Pre-competitive public infrastructure

Perhaps the most pressing issue for governments today is to develop the basic pre-competitive infrastructure and innovation ecosystems for engineering biology. An interesting test case is the United Kingdom, which has invested since 2014 some GBP 350 million in synthetic and engineering biology infrastructure, comprising basic research centres, biofoundries and an industrial translation centre. Since then, around 180 engineering biology companies have been launched, and public investment has leveraged approximately a six-fold private investment.3

Business risks in the value chain

Bio-based value chains often find themselves in direct competition with fossil-based value chains. This represents a high hurdle, especially if bio-based products are to conform to the higher standards demanded by sustainability. Without attention to sustainability and carbon footprints, bio-based value chains will not be compatible with climate-change objectives.

Bio-based value chains are new and unproven. Although the technologies and ambitions of engineering biology are attractive, investors will look to the entire value chain. If weaknesses are apparent, from the feedstocks to the products and even beyond (e.g. end of life for bioplastics), investors may look elsewhere. This represents a “systemic business risk” (Marvik and Philp, 2020[29]). This risk is especially important in small countries: even small advanced countries can suffer from a lack of home-grown biotechnology, which has to be imported. Providing the public infrastructure described above is one way to address this, so that investors and the private sector are confident that a government is serious about promoting engineering biology in a sustainable manufacturing future.

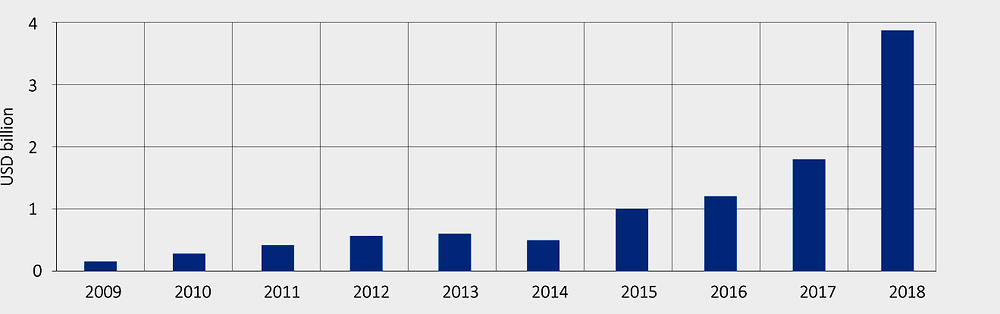

That being said, global private-sector investments in synthetic biology have increased steadily year on year since 2009, with a significant acceleration in 2018 (Figure 7.5). Investments came from a variety of sources: established biotechnology firms like Bayer and Novartis, investment groups such as SoftBank and start-up accelerators.

The United States and the United Kingdom are the most prominent investors in synthetic biology start-ups, with over USD 12 billion invested so far (Clarke and Kitney, 2020[30]). To date, health-related biotechnology applications have dominated product commercialisation. Synthetic biology start-ups developing tools and services account for between 10% (in the United Kingdom) and 25% (in the United States) of private investment activity.

Around 20% of synthetic biology start-ups address industrial biotechnology targets, but they currently only attract around 11% in private investment, often due to the scale-up issue discussed above. While there exist some key technical barriers to scale-up, a number of policy interventions could help overcome some of the difficulties. (Clarke and Kitney, 2020[30]) cite the need for the various stakeholders to adopt a more networked approach linking specialists, infrastructure and ongoing research to de-risk the economic challenges of scale-up. If governments see this as part of the future of manufacturing, then an effective long-term funding strategy is needed, but one that addresses the outstanding scale-up issues. A promising field in this regard is cell-free synthetic biology as the presence of the microbial cell itself is responsible for some scale-up difficulties (Kelwick, Webb and Freemont, 2020[31]).4

Previous OECD work has highlighted that balanced measures on both the supply and demand side are needed in order to diffuse a technology (OECD, 2011[32]). Bioeconomy policies face this balancing act across diverse sectors, including industrial manufacturing, agriculture, forestry, marine resources and waste management. Many bioeconomy forums, including multiple OECD workshops (Philp and Winickoff, 2019[8]), highlight the need for a wide range of supply- and demand-side policies. Governments have traditionally preferred supply-side measures, yet demand-side measures, such as public procurement of bio-based products, would send strong signals to bioeconomy stakeholders.5 This is not easy for various reasons. Public procurers are known to be cost-sensitive, and many bio-based products (such as bioplastics) still struggle to compete with their fossil equivalents on price. The United States Department of Agriculture (USDA) BioPreferred Program6 is the only prominent example of a successful public procurement policy for bio-based products that specifies sustainability criteria. To date, the USDA has identified 139 categories of bio-based products for which agencies and their contractors have purchasing requirements. Each mandatory purchasing category specifies the minimum bio-based content for products within the category.

Policy co-ordination

All of the policy areas highlighted above need to be addressed to avoid value-chain weaknesses and failure. This is a whole-of-government issue that needs to be co-ordinated. A good approach might be to establish an independent advisory body, akin to the German Bioeconomy Council.7 Such a body could help align diverse ministries and facilitate the interaction of government and industry. If a country possesses a synthetic biology or engineering biology roadmap, the advisory body could be asked to ensure that its milestones and deadlines are met.

Roadmaps themselves can also be used as policy co-ordination tools, although synthetic biology roadmaps are currently rare and have different intentions. Investments in centres of excellence and technology platforms, as well as in accelerating technology to market, are the most common steps being considered (Table 7.1).

Public acceptance

Another important, but often overlooked, issue is public acceptance (OECD, 2017[35]); see Chapter 8 in this volume). As engineering biology applications become more entrenched in future markets, the representative organisations will become increasingly visible to the public. To avoid repeating past mistakes in communicating around genetically modified organisms, scientists, technologists, practitioners and policy makers need to work closely with biofoundry operators and the public to shape and guide future developments (Dixon, Curach and Pretorius, 2020[36]).

Digital security: An emerging threat for policy makers

There exist many ways to launch a cyberattack on a bio-production company. The convergence and integration of robotics, microfluidics, cell-free systems design, synthetic metabolic engineering and other technologies will reveal new vulnerabilities and offer new opportunities for nefarious actions (Richardson et al., 2019[37]).

The ability to separate design from manufacturing completely could heighten such threats. Ultimately, design will be possible from any location (including home), exacerbating potential threats to manufacturing facilities. Many different types of organisations are involved in bio-production security, from feedstock suppliers, through information technology professionals at law firms and IP offices, to customers. Digital security is only as strong as the weakest link in the overall system of protection, and calls for co-operation across many private and public institutions. Moreover, because attacks can also be launched by hostile governments, countries must act to develop the policy and infrastructure to prevent cyber-attacks (OECD, 2020[38]).

Given the current context of multiple sustainability crises and now the COVID-19 pandemic, science, technology and innovation (STI) systems are redirecting their efforts towards grand challenges, and reimagining in the process the ends and means of technological development (see Chapter 8). The health crisis has only accelerated the trend towards a greater mission orientation in the STI system, highlighting the importance of steering technology to address the most pressing problems. Clearly, many kinds of socio-technical solutions will need to be pursued simultaneously to address the uncertainties and complex challenges facing humanity.

This chapter has explored how engineering biology might contribute in time to novel approaches towards vaccine development and sustainability, given the new salience of mRNA approaches and the new-found convergence between the biotechnology and digital technologies embodied in the biofoundry. Significant policy and technological barriers exist, and will need to be addressed. The payoffs are potentially large: technological developments might open up new opportunities for manufacturing across a range of sectors and for a wide range of products, whether medicines, new materials or greener chemicals.

In the context of the current COVID-19 pandemic, this chapter has argued that engineering biology provides a model that is well-suited to overcoming the shortcomings of modern vaccine, diagnostics and antibody production. Looking towards the future, the opposite is also true. For a domain like engineering biology, in which the promise frequently outstrips the reality in terms of the actual economic and social impact, the COVID-19 crisis is an opportunity to realise the overall potential of the field. Such successes, if they can be accomplished, would bolster public confidence in these technologies.

With the emergence of viable mRNA vaccine approaches against COVID-19, and other developments in biotechnology, it is clear how engineering biology could be leveraged to address significant global challenges – not only for vaccines, but also cancer treatment, personalised medicine, sustainable fuels and industrial chemicals, remediation of polluted environments and food supplies. But research is far from capitalising on its fullest potential.

Figure 7.4 outlines many tracks for future policy options. To develop the field, governments could:

establish pre-competitive infrastructure and collaborative platforms, such as networked biofoundries and research consortia, by ensuring long-term and stable funding for engineering biology research and translational infrastructures, and accelerate its commercialisation by supporting the growth of an ecosystem of start-ups;

address systemic business risk in bio-based value chains, e.g. by supporting translation and testing of technical scaling activities, including access to technical expertise and guidance, as well as equipment for start-ups and smaller businesses;

support engagement of scientists, technologists, practitioners and policy makers with biofoundry operators, members of the public and stakeholder groups, to promote trust in (and trustworthiness of) the technology;

support strong science-industry collaboration, e.g. by introducing support specific to these types of risky technologies, such as proof-of-concept funding, to determine whether larger-scale collaboration is warranted; and

build multidisciplinary environments and transdisciplinary skills to promote convergence (as engineering biology extends beyond traditional discipline boundaries, drawing from engineering, biology, data science and physical sciences, and multidisciplinary environments are key to its success), and rely on people who can communicate across disciplines.

References

[20] Babb, P. et al. (2017), “The Nephila clavipes genome highlights the diversity of spider silk genes and their complex expression”, Nature Genetics, Vol. 49/6, pp. 895-903, https://doi.org/10.1038/ng.3852.

[3] Cameron, D., C. Bashor and J. Collins (2014), “A brief history of synthetic biology”, Nature Reviews Microbiology, Vol. 12/5, pp. 381-390, https://doi.org/10.1038/nrmicro3239.

[1] Cayuela Valencia, R. (2013), The Future of the Chemical Industry by 2050, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, https://doi.org/10.1002/9783527656998.

[7] Chao, R. et al. (2017), “Engineering biological systems using automated biofoundries”, Metabolic Engineering, Vol. 42, pp. 98-108, https://doi.org/10.1016/j.ymben.2017.06.003.

[19] Check Hayden, E. (2014), “Synthetic-biology firms shift focus”, Nature, Vol. 505/7485, pp. 598-598, https://doi.org/10.1038/505598a.

[30] Clarke, L. and R. Kitney (2020), “Developing synthetic biology for industrial biotechnology applications”, Biochemical Society Transactions, Vol. 48/1, pp. 113-122, https://doi.org/10.1042/bst20190349.

[22] Coley, C. et al. (2019), “A robotic platform for flow synthesis of organic compounds informed by AI planning”, Science, Vol. 365/6453, p. eaax1566, https://doi.org/10.1126/science.aax1566.

[13] Crone, M. et al. (2020), “A role for Biofoundries in rapid development and validation of automated SARS-CoV-2 clinical diagnostics”, Nature Communications, Vol. 11/1, https://doi.org/10.1038/s41467-020-18130-3.

[16] Devaney, L. (2016), “Imagine the future”, Taste of Science, Wageningen, the Netherlands, http://www.tasteofscience.com/articles/609/imagine-the-future.html (accessed on 9 July 2020).

[36] Dixon, T., N. Curach and I. Pretorius (2020), “The convergence of artificial intelligence and synthetic biology”, EMBO Reports, 21: e50036, https://www.embopress.org/doi/pdf/10.15252/embr.202050036.

[33] EBRC (2019), “Engineering biology. A research roadmap for the next‐generation bioeconomy”, EBRC, Emeryville, California, https://ebrc.org.

[27] Extance, A. (2016), “How DNA could store all the world’s data”, Nature, Vol. 537/7618, pp. 22-24, https://doi.org/10.1038/537022a.

[2] Griffin, P., G. Hammond and J. Norman (2018), “Industrial energy use and carbon emissions reduction in the chemicals sector: A UK perspective”, Applied Energy, Vol. 227, pp. 587-602, https://doi.org/10.1016/j.apenergy.2017.08.010.

[10] Hillson, N. et al. (2019), “Building a global alliance of biofoundries”, Nature Communications, Vol. 10/1, https://doi.org/10.1038/s41467-019-10079-2.

[6] Horváth, I. (2018), “Introduction: Sustainable Chemistry”, Chemical Reviews, Vol. 118/2, pp. 369-371, https://doi.org/10.1021/acs.chemrev.7b00721.

[31] Kelwick, R., A. Webb and P. Freemont (2020), “Biological Materials: The Next Frontier for Cell-Free Synthetic Biology”, Frontiers in Bioengineering and Biotechnology, Vol. 8, https://doi.org/10.3389/fbioe.2020.00399.

[34] Le Feuvre, R. and N. Scrutton (2018), “A living foundry for Synthetic Biological Materials: A synthetic biology roadmap to new advanced materials”, Synthetic and Systems Biotechnology, Vol. 3/2, pp. 105-112, https://doi.org/10.1016/j.synbio.2018.04.002.

[29] Marvik, O. and J. Philp (2020), “The systemic challenge of the bioeconomy”, EMBO reports, Vol. 21/10, https://doi.org/10.15252/embr.202051478.

[23] Mertens, R. (2018), The Graphene Handbook (2018 edition), Lulu.com, https://www.bokus.com/bok/9781387434398/the-graphene-handbook-2018-edition/.

[14] National Academies of Sciences, Engineering, and Medicine (2020), “Public Listening Session: Discussion Draft of the Preliminary Framework for Equitable Allocation of COVID-19 Vaccine”, The National Academies Press, Washington, DC, https://www.nationalacademies.org/event/09-02-2020/public-listening-session-discussion-draft-of-the-preliminary-framework-for-equitable-allocation-of-covid-19-vaccine.

[11] National Academies of Sciences, Engineering, and Medicine (2020), Safeguarding the Bioeconomy, National Academies Press, Washington, D.C., https://doi.org/10.17226/25525.

[38] OECD (2020), “Digitalisation in the bioeconomy: Convergence for the bio-based industries”, in The Digitalisation of Science, Technology and Innovation: Key Developments and Policies, OECD Publishing, Paris, https://dx.doi.org/10.1787/bd16d851-en.

[39] OECD (2018), SMEs in Public Procurement: Practices and Strategies for Shared Benefits, OECD Public Governance Reviews, OECD Publishing, Paris, https://dx.doi.org/10.1787/9789264307476-en.

[35] OECD (2017), The Next Production Revolution: Implications for Governments and Business, OECD Publishing, Paris, https://dx.doi.org/10.1787/9789264271036-en.

[28] OECD (2014), Emerging Policy Issues in Synthetic Biology, OECD Publishing, Paris, https://dx.doi.org/10.1787/9789264208421-en.

[32] OECD (2011), Demand-side Innovation Policies, OECD Publishing, Paris, https://dx.doi.org/10.1787/9789264098886-en.

[4] Opgenorth, P. et al. (2019), “Lessons from Two Design–Build–Test–Learn Cycles of Dodecanol Production in Escherichia coli Aided by Machine Learning”, ACS Synthetic Biology, Vol. 8/6, pp. 1337-1351, https://doi.org/10.1021/acssynbio.9b00020.

[8] Philp, J. and D. Winickoff (2019), “Innovation ecosystems in the bioeconomy”, OECD Science, Technology and Industry Policy Papers, No. 76, OECD Publishing, Paris, https://dx.doi.org/10.1787/e2e3d8a1-en.

[37] Richardson, L. et al. (2019), “Cyberbiosecurity: A Call for Cooperation in a New Threat Landscape”, Frontiers in Bioengineering and Biotechnology, Vol. 7, https://doi.org/10.3389/fbioe.2019.00099.

[25] Seo, D. et al. (2017), “Single-step ambient-air synthesis of graphene from renewable precursors as electrochemical genosensor”, Nature Communications, Vol. 8/1, https://doi.org/10.1038/ncomms14217.

[9] Srai, J. et al. (2016), “Distributed manufacturing: scope, challenges and opportunities”, International Journal of Production Research, Vol. 54/23, pp. 6917-6935, https://doi.org/10.1080/00207543.2016.1192302.

[21] Suitor, J., S. Varzandeh and S. Wallace (2020), “One-Pot Synthesis of Adipic Acid from Guaiacol in Escherichia coli”, ACS Synthetic Biology, Vol. 9/9, pp. 2472-2476, https://doi.org/10.1021/acssynbio.0c00254.

[17] U.S. Government Accountability Office (2018), “Considerations for maintaining U.S. competitiveness in quantum computing, synthetic biology, and other potentially transformational research areas”, Report to the Subcommittee on Research and Technology, Committee on Science, Space, and Technology, House of Representatives, United States Government Accountability Office, GAO-18-656, https://www.gao.gov/assets/700/694748.pdf.

[40] UK Synthetic Biology Coordination Group (2012), “A synthetic biology roadmap for the UK”, Technology Strategy Board July, T11/070, Technology Strategy Board on behalf of UK Synthetic Biology Roadmap Coordination Group, Swindon.

[12] Ulmer, J., M. Mansoura and A. Geall (2015), “Vaccines ‘on demand’: science fiction or a future reality”, Expert Opinion on Drug Discovery, Vol. 10/2, pp. 101-106, https://doi.org/10.1517/17460441.2015.996128.

[15] Weintraub, R., A. Bitton and M. Rosenberg (2020), “The Danger of Vaccine Nationalism”, Harvard Business Review, 22 May, https://hbr.org/2020/05/the-danger-of-vaccine-nationalism.

[18] Westfall, P. and T. Gardner (2011), “Industrial fermentation of renewable diesel fuels”, Current Opinion in Biotechnology, Vol. 22/3, pp. 344-350, https://doi.org/10.1016/j.copbio.2011.04.023.

[5] Wu, W. and C. Maravelias (2019), “Identifying the Characteristics of Promising Renewable Replacement Chemicals”, iScience, Vol. 15, pp. 136-146, https://doi.org/10.1016/j.isci.2019.04.012.

[24] Ye, M. et al. (2018), “Graphene Platforms for Smart Energy Generation and Storage”, Joule, Vol. 2/2, pp. 245-268, https://doi.org/10.1016/j.joule.2017.11.011.

[26] Zhirnov, V. et al. (2016), “Nucleic acid memory”, Nature Materials, Vol. 15/4, pp. 366-370, https://doi.org/10.1038/nmat4594.

Notes

← 1. https://www.weforum.org/agenda/2015/03/top-10-emerging-technologies-of-2015-2/ (accessed 15 September 2020).

← 2. https://twistbioscience.com/products/storage (accessed 10 July 2020).

← 3. Richard Kitney, personal communication.

← 4. At the time of writing, an annual conference held in Canada is dedicated solely to scale-up. Learn more at: https://www.scalingupconference.ca/ (accessed 15 September 2020).

← 5. In OECD member countries, public procurement accounts for 12% of gross domestic product on average and 29% of total government expenditures, with a significant effect on trade flows (OECD, 2018[39]).

← 6. https://www.biopreferred.gov/BioPreferred/ (accessed 15 September 2020).

← 7. https://biooekonomierat.de/en/ (accessed 10 July 2020).