Chapter 5. Mining and the environment

Oil shale mining and use are the dominant source of environmental impact in Estonia. While pollution releases from the sector have declined over the last decade, major challenges remain with respect to waste management, air and water quality, particularly in north-eastern Estonia. This chapter provides an overview of trends in the extraction and use of oil shale and other mineral resources, highlights the related environmental impacts and analyses the effectiveness of policy instruments Estonia applies to address them.

1. Introduction

Estonia has abundant deposits of oil shale, construction minerals and peat. Construction minerals such as sand, gravel, clay and limestone account for half of all mineral deposits by volume, while combustible minerals represent the other half and include oil shale and peat (Valgma, 2012).

The oil shale deposit is the most commercially exploited in the world, accounting for about 80% of its global extraction (Box 5.1). Oil shale is Estonia’s most important energy-rich mineral resource: it provided around 70% of the country’s total primary energy supply and 83% of electricity in 2015 (IEA, 2016a; Chapter 1), making Estonia one of the most energy-independent countries of Europe. Still, oil shale mining and use account for only 4% of gross domestic product (GDP) (IEA, 2013) and 1.5% of employment (Rell and Kupts, 2014). Estonia has to balance the domestic economic and security benefits of oil shale exploitation with its environmental costs: oil shale mining and use cause the country’s most important environmental impacts (Section 4).

Oil shale, one of the most prolific hydrocarbon resources on Earth, is a sedimentary rock containing up to 50% kerogen, a solid mixture of organic chemical compounds. Massive deposits are found in a number of countries around the globe, including Australia, Brazil, the People’s Republic of China (hereafter China), Estonia, Israel, Jordan and the United States, but most are too deep or too costly to be exploited. Today, only China and Estonia produce oil shale commercially.

Once extracted from the ground, the rock can be used in thermal power plants to produce electricity or heat. It can also be processed by applying heat to produce crude oil and valuable chemicals, such as phenols. Crude oil produced from oil shale is called shale oil (a type of synthetic oil extracted from shale by pyrolysis), and can be refined into diesel, jet fuel, motor gasoline and natural gas liquids. In Estonia, over 80% of the mined oil shale is used to produce electricity and heat; the rest is used to produce shale oil and chemicals.

Source: Batkhuyag and Yondongombo (2012); IEA (2013).

Estonia also has considerable peat resources: over 1 million hectares (ha) of its territory is covered by peatlands, constituting 22.5% of the total land area. Highly decomposed peat is mainly used as heating material. The Rakvere phosphate rock deposit is the largest in Europe. For technological reasons, it is not being mined and is, therefore, not covered in this chapter.

2. Policy framework for minerals management

National development plans guide the management of mineral resources. Their main purpose is to ensure the long-term availability of the resources and to prevent and mitigate environmental impacts. The process for preparing a national Earth’s Crust Strategy was launched in early 2015 and should be completed by the end of 2017. The Estonian Environmental Strategy 2030 (adopted in 2007) introduced the objective of environmentally sustainable mining without stipulating specific measures.

The main elements of the regulatory framework for the mining and use of mineral resources are the Earth’s Crust Act (2004, last amended in 2015) and the Mining Act (2003). A draft new Earth’s Crust Act was sent to Parliament in April 2016 as part of the environmental law codification effort (Chapter 2). The use of oil shale in combustion plants and shale oil production is also regulated by certain provisions of the Ambient Air Protection Act (1998), the Waste Act (2004) and the Industrial Emissions Act (2016).

2.1. Oil shale

The National Development Plan (NDP) for Oil Shale Use for 2008-15 had three strategic goals: to guarantee oil shale supply to ensure the country’s energy independence; to increase the efficiency of oil shale mining and use; and to reduce the environmental impact of oil shale (MoE, 2008). The energy independence goal, which favoured electricity generation based on oil shale over export-oriented shale oil production, has lost its relevance since Estonia became a member of the Nord Pool open electricity market (Chapter 1). Energy security can now be guaranteed through a combination of self-reliance and increased diversity of energy suppliers. The Oil Shale NDP for 2016-30 adopted by Parliament in March 2016 no longer presents oil shale as a stake in the country’s energy independence (MoE, 2015a).

The other two goals of the NDP 2008-15 (increased efficiency and reduced environmental impact) had not been achieved by 2015 (NAO, 2014) and were included again in the NDP 2016-30. The new NDP defines a number of indicators and respective 2020 targets1 with respect to efficiency and environmental impact of oil shale mining and use. However, these targets are not ambitious and commonly call for maintaining 2013 performance levels. Without a comprehensive assessment of the environmental, health and socio-economic consequences of oil shale production and use, the new NDP is unlikely to address the sector’s actual negative impacts (NAO, 2014). Importantly, neither the previous nor the current NDP describes specific activities to reduce oil shale waste generation. At the same time, the NDP 2016-30 also assigns priority to applied research and development (R&D) in the oil shale sector, but proposes to raise it from approximately EUR 520 000 to just EUR 600 000 in 2020 (MoE, 2015a). As the sector’s technological know-how advances, more ambitious targets for 2025 and 2030 would need to be formulated and accompanied by specific implementation measures.

Other NDPs that affect the use of oil shale are the recently adopted National Development Plan of the Energy Sector until 2030 and the Development Plan of the Electricity Sector until 2018. The energy and electricity plans aim primarily at determining how much oil shale is required by the economy. The Energy Development Plan ensures consistency throughout all the plans related to energy by including targets and measures from other development plans (NAO, 2014). The General Principles of the Climate Policy until 2050 envisages a shift from combustion to more extensive processing of oil shale into higher value-added products, thereby reducing greenhouse gas (GHG) emissions.

Despite the broad policy coverage of the oil shale sector, the coherence of separate strategies and action plans, especially in terms of inter-ministerial co-ordination, remains a challenge. For example, the Estonian Environmental Strategy envisaged in 2007 a reduction of annual oil shale extraction compared to the 2005 baseline of 11 million tonnes (t), which did not happen; the NDP 2008-15 and the Earth’s Crust Act stipulated an annual limit of 20 million t (Section 5.1).

2.2. Peat

The main principles of peatland protection and sustainable use are stated in the draft concept paper “Protection of Estonian Peatlands and Principles of Sustainable Use” (MoE, 2010). The concept paper emphasised the importance of balancing the economic benefits and environmental effects of peat use. It advocated the concentration of peat mining in existing peat production areas, as well as the reuse or restoration of abandoned peat production areas.

There were plans to use this paper as a basis for a proposal for a peatland protection and sustainable use plan. The concept paper has never been formally adopted, but its objectives will be integrated into the Earth’s Crust Strategy that is being developed.

2.3. Construction minerals

The National Development Plan for Mineral Resources Used in the Construction Industry for 2010-20 set priorities for mining and use of construction minerals. Its strategic objectives include increasing the efficiency of construction mineral mining and use, expanding the use of alternative construction materials and reducing the sector’s environmental impacts. The National Development Plan identifies waste rock from oil shale mining as an important resource for construction and encourages its wider use.

There is no extraction limit for construction minerals. As 92% of the mined construction minerals are used within Estonia, the government considered that setting such a limit could constrain construction activities, including infrastructure projects of national importance. However, NAO (2009) believed that issuing extraction permits based on national annual mining rates would make the extraction of minerals considerably more efficient.

3. Extraction and use of mineral resources

3.1. Oil shale

The oil shale deposits lie in an area of about 2 000 km2 in the north-eastern part of the country (Figure 5.1). The best reserves in terms of their calorific value are found in the central and eastern part of the deposit and will be exhausted over the next decade. Therefore, mining activities will move towards the western and southern parts of the deposit, which contain lower quality reserves (EASAC, 2007).

Source: Valgma, I. (2001), Map of the Baltic Oil Shale Area, www.ene.ttu.ee/maeinstituut/poster/rez.html.

The deposits amount to nearly 4.7 Giga-tonnes, including about 1.3 Giga-tonnes of active (extractable) reserves (NAO, 2014). At the extraction rate of 20 million t per year and considering substantial mining losses, the active consumable (sufficiently investigated) reserves would last for about 50 years (MoE, 2014). The 2014 extraction rate was almost 15 million t (Statistics Estonia, 2016).2

Since 2009, more than half of Estonia’s mined oil shale has come from underground mines (Gaškov et al., 2012). Based on the World Energy Council’s forecasts (All, 2014), underground mines are expected to constitute 80% of all mines by 2020. The extraction technology is more complex for underground mining than for open-cast mining due to the deeper bedding of oil shale deposits. The process leads to greater losses: almost one-third of resources are left behind in pillars and/or unmined areas. In 2013, mining losses accounted for 8% of the total production in open-cast quarries and for 29% in underground mines (NAO, 2014).

Both the shift to underground mining and the exploration of lower-quality reserves are expected to reduce the profitability of oil shale mining. The NDP for Oil Shale Use for 2008-15 did not indicate the optimal level of efficiency improvements needed to maintain the sector’s economic viability, or put forward any measure for reducing mining losses. The NDP 2016-30 sets a target of maintaining losses in underground mines below the 2013 base, but does not contain measures to reduce them further (MoE, 2015a).

Four oil shale mining companies hold excavation permits: the state-owned Eesti Energia Kaevandused (part of the Eesti Energia Group) and three private firms. The extraction is heavily concentrated. In 2012, Eesti Energia mined around 13 million t of oil shale, accounting for 88% of the total extracted in Estonia and making it the largest oil shale processing company in the world (NAO, 2014).

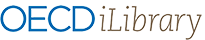

Compared to other solid fuels, oil shale does not have a high export potential (All, 2014). However, products of oil shale – shale oil, chemicals and electricity – can be profitably exported. Export demand for electricity and shale oil (coming primarily from Latvia and Lithuania) drove increased extraction of oil shale in the last decade (Figure 5.2). High global oil prices in 2009-14 increased the profitability of using oil shale for fuel production and motivated oil shale companies to actively invest in additional shale oil production capacities (Figure 5.3).

The drop of global oil prices over 2014-15 has heavily reduced the profitability of shale oil production: Eesti Energia’s net profit fell by 66% during the period (Eesti Energia, 2016). This has forced companies to freeze production, lay off workers and put their long-term investment plans on hold. A recent study estimated that approximately 75% of the oil shale processing equipment will reach the end of its economic life by 2025. The same study estimated that an increase of CO2 prices to EUR 100 per tonne by 2035 instead of EUR 20 per tonne (in real terms) could decrease the cash flow per tonne of oil of the sector’s companies by about 30% (Ernst and Young, 2014).

Oil shale combustion for electricity generation is expected to stabilise in the coming years before declining due to increased competition for electricity exports in the Nord Pool market and limited replacement by renewables (most Estonian boilers designed for oil shale combustion can accommodate partial or complete fuel switching to biomass). Oil shale use for heat will continue to decline as current policies favour its replacement with biomass in combined heat and power plants; only 13% of heat supply now comes from oil shale. Shale oil production prospects are uncertain in light of low global oil prices (Kearns, 2015). The same is true for Estonia’s longer-term plans to capture semi-coke gas, a by‐product of shale oil production, and use it as a fuel for electricity and heat generation.

To ensure the sector’s viability, Estonia should invest to improve efficiency of oil shale extraction, power generation and shale oil production. Some investments have been made: new shale oil production units and new fluidised bed combustion units in power plants are more efficient than old ones. In 2011, the oil shale sector accounted for a quarter of the total R&D expenditures. However, this share went down to 17% in 2014 (IEA, 2016b). According to NAO (2015), the government had not achieved its goal, set in the NDP 2008-15, of raising the efficiency of mining and using oil shale.

More investments are needed to develop new mining and processing technologies, although this may be difficult under currently unfavourable market conditions. Research continues into loss-reducing mining technologies, some of them including backfilling with waste rock to allow more extraction of oil shale without risking land subsidence (Karu et al., 2008; Tohver, 2011). In addition to the reference document on best available techniques (BAT) for shale oil production developed in Estonia in 2013, the NDP for Oil Shale Use for 2016-30 envisages a BAT reference document on the use of oil shale for energy generation3 by mid-2017 (MoE, 2015a). An EU BAT reference document on mining waste management is also under preparation.

More generally, the government needs to take concrete action towards diversification of the energy supply by ensuring a more even distribution of energy sources (IEA, 2013). As a member of the Nordic Electric Exchange since 2009, Estonia is a participant in an open electricity market. Thus it does not have to rely on domestic sources for power supply.

The diversification of the energy supply and the consequent decline in demand for oil shale would entail the need to offer social guarantees to the oil shale sector’s mostly Russian-speaking work force in north-eastern Estonia. Estonia recently submitted an application for support from the Globalisation Adjustment Fund to mitigate the impact of job cuts in Ida-Viru county. The experience of Germany’s Ruhr region may provide insight into the transition from an economy based on natural resources to a knowledge-based economy (Galgóczi, 2014). Based on Germany’s experience, a socially responsible downsizing process may include labour market transition of dismissed workers through employment promotion and retraining managed by specialised agencies, as well as early retirement. Although the transition would mostly affect men, job creation for female employees should also be an important priority. Finally, active collaboration between the central government, municipalities, employers and trade unions is essential for a successful and just transformation.

3.2. Peat

Estonia’s peat areas cover 1.2 million ha, or 22.5% of the territory. As of the end of 2014, the active reserves of peat suitable for mining were about 198 million t. Currently, there are 208 registered peat mining areas, of which 62 were in active use in 2014 (MoE, 2006-14). Around 65% of peat production is exported. Around 60% of the peat consumed domestically is used to make gardening products, while the rest is burned for household heating (Eesti Turbaliit, 2016).

In 2006, a government regulation established an annual peat extraction quota of 2.6 million tonnes. The limit is divided between counties to guarantee an even distribution of production sites. During the last decade, the peat extraction volumes have fluctuated between 0.6 and 1.2 million t per year depending on weather conditions. The government plans to decree where extraction of peat deposits is acceptable from economic and environmental perspectives.

3.3. Construction minerals

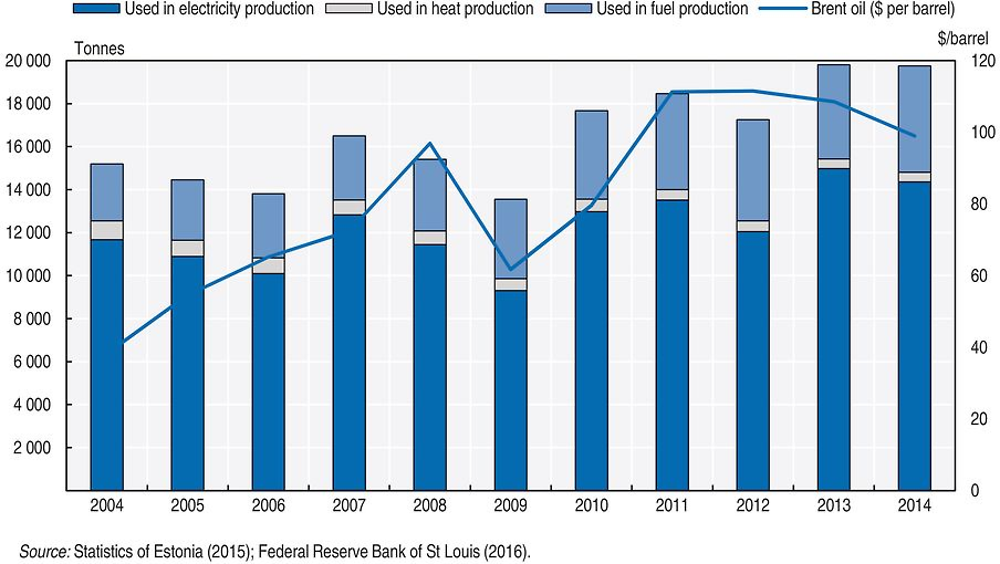

Sand, gravel and limestone are the most widely used construction minerals in Estonia. Sand and gravel are used in the building materials industry to make concrete and other mixes, as well as in road construction. Limestone is used in the construction of buildings and roads. Dolomite rock is used in the production of crushed stone, masonry stones, pavement slabs, stairs, etc.

More than 200 small companies mine construction minerals in open quarries. Since 2007, the extraction of sand and gravel accounted for about 65-70% of all extracted construction minerals (Figure 5.4). Over the last ten years, the demand for construction materials was largely driven by investments of EU structural funds into road infrastructure. During the rapid economic growth of 2006-07, road construction materials – limestone and gravel – were most in demand. The economic crisis in 2008 resulted in less mining of all minerals; since 2011, mineral volumes have started to gradually increase, but have not reached pre-crisis levels.

4. Environmental impacts and main mitigation measures

Oil shale is the country’s largest source of hazardous and non-hazardous industrial waste. Approximately half the material extracted in oil shale mining becomes waste rock, consisting of limestone and oil shale residue; this accounts for 70% of the country’s non-hazardous waste generation (Chapter 4). Oil shale processing generates up to 98% of the country’s hazardous waste (Eurostat, 2015). This includes ash from oil shale combustion, as well as semi-coke and retorting waste from its conversion to shale oil.

Oil shale mining has harmful environmental impacts on water abstraction and the quality of both surface water and groundwater (NAO, 2014). Air pollution from the oil shale sector comprises more than 70% of all Estonia’s air emissions (NAO, 2014). The industry (including state-owned Eesti Energia) spent EUR 366 million in 2011-14 alone to reduce pollution caused by oil shale mining and processing (Statistics Estonia, 2015), but major challenges remain.

Other environmental impacts of oil shale mining are related to noise, vibration, sinkholes and floods. These factors reduce the value of properties and land, damage landscapes and buildings, and negatively affect the social fabric of local communities. None of these aspects has yet been analysed in detail, making it difficult to design mechanisms to address them (NAO, 2014).

Peat mining has considerable impacts on ecosystem and hydrological balance. The restoration of dehydrated peat lands and protection of existing wetlands are important challenges in Estonia. Special focus is needed for abandoned production fields. If these areas are not re-vegetated, they constitute an important source of CO2 emissions (Karofeld, 2004).

Mining of other minerals also causes problems of waste disposal, but of a lesser scale. Mining of construction minerals generates waste in the form of siftings and dust. Siftings are used as a filling material in construction activities or for backfilling of mines. In addition, NAO (2009) noted the extraction of minerals in Estonia does not usually involve environmental mitigation and that old quarries are usually not reconditioned.

4.1. Non-hazardous mining waste

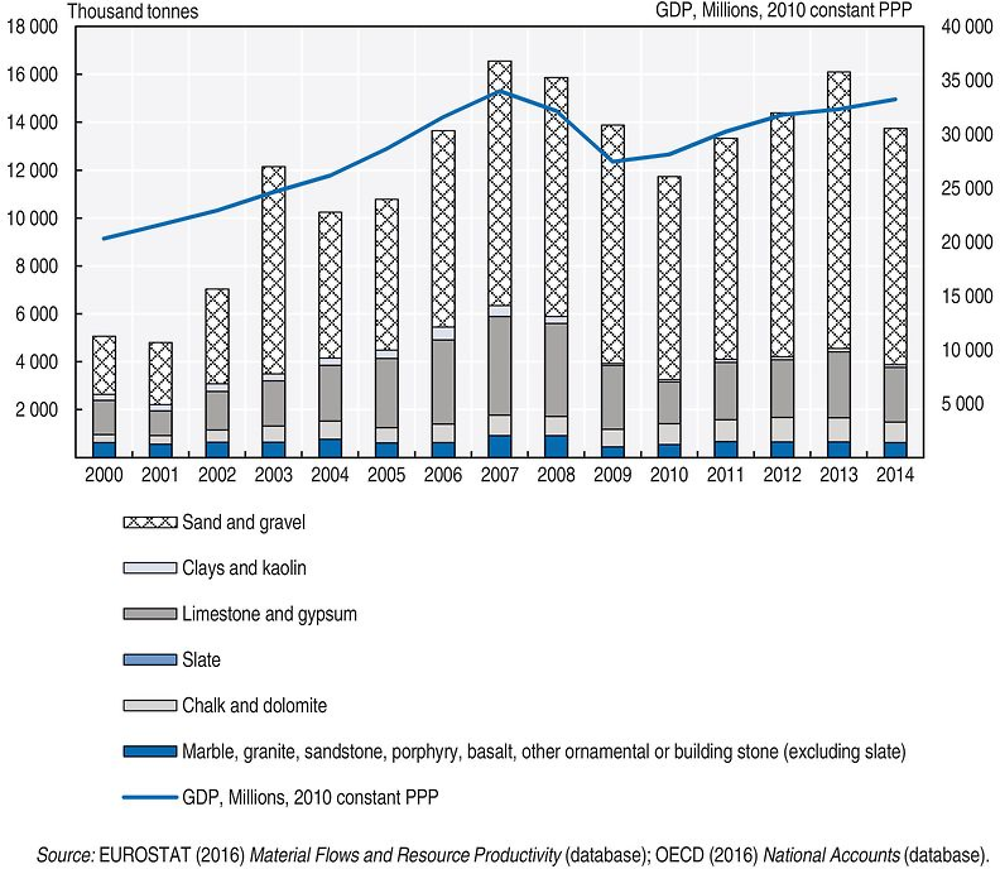

Mining waste generation has increased by about 40% since 2005 due to growth in total extraction volume (Figure 5.5). According to NAO (2014), this increase is caused by extraction of oil shale of increasingly lower quality. In addition, mining waste generated by the Narva quarries was not reported until 2011; this suggests the increase in mining waste is, at least partly, related to changes in waste reporting (NAO, 2014).

The amount of waste rock depends on the mining technology: underground mining generates up to half a tonne of mining waste for every tonne of extracted oil shale, which is significantly more than open-cast mines. In the foreseeable future, mining waste amounts are likely to increase due to more extensive underground mining and exploitation of lower quality reserves (Section 3.1).

Waste rock is usually sorted into low-quality gravel (for road construction or backfilling) and oil shale residues. Oil shale residues are deposited in landfills because it is not economically feasible to reuse them. One study estimates that all waste deposited in landfills contains more oil shale than what is annually extracted (Gaškov et al., 2012). The risk of self-ignition and leaching, with consequent negative impacts on air quality and groundwater, is particularly high in Soviet-era landfills, where the oil shale content in waste is very high.

Between 2005 and 2012, the share of recovered waste rock went from 20-25% to more than 90%, before declining to 45% in 2014 (Figure 5.5). Using gravel made from waste rock as ground filler for building a local moto-centre, as well as in several large-scale road construction projects, explains the high reuse percentage of 2011-12 (Gaškov et al., 2012). However, the NDP 2016-30 sets the waste rock reuse target for 2020 below levels that have already been achieved, at just 40% (MoE, 2015).

Eesti Energia, the main mining company, has invested in crushed stone production facilities. Due to the low value of waste rock (and the low quality of gravel produced from it) and the comparatively high transportation costs, reuse opportunities depend on local construction. Indeed, the fall in the reuse of mining waste over 2012-14 appears to be linked to the completion of local construction projects. The demand for waste rock is partly sustained by the fact that several big limestone quarries in Harju county are on the verge of depletion; plans to open up new quarries have not been well received by local communities. In coming years, a share of waste rock from oil shale mining could be used as construction material for the upcoming Rail Baltica project (Box 5.2); however, the economic costs and environmental impacts will need to be carefully assessed.

In the coming years, Estonia together with Latvia and Lithuania plan to construct Rail Baltica, a transport link to other parts of Europe financed in part with EU support. For much of this line, new tracks will be built, with work indicated (as of early 2016) to begin in 2017. The Estonian government has commissioned a feasibility study on the use of limestone waste from oil shale mining for the construction. While the quality of the rock is not appropriate for the track ballast, it could be used for complementary works. However, its transport from oil shale mining areas in north-eastern Estonia would result in both direct costs and environmental impacts.

Source: Rail Baltica (2016).

Old quarries are also commonly used to plant forests for commercial logging. In addition, the academic community has proposed to use quarries to build wind farms, turning waste hills into ski slopes or observation points, but in practice only a few have been transformed (Virkus, 2014). The government foresees greater use of underground mines and introduction of backfilling of mining waste into galleries after extraction. This recovery method should reduce surface movements and improve mine safety and mining operations, but it will entail higher costs.

4.2. Hazardous waste from oil shale combustion and refining

The quantity of hazardous waste generated in 2014 was about 9 million t of oil shale ash and 1 million t of semi-coke. This is 48% more than in 2005 (Figure 5.6) due to more oil shale combustion and refining (Figure 5.2) and insufficient improvements in the respective technologies.

Ash

Oil shale is burned in power plants, as well as in combined heat and power plants, near the main oil shale mining area; this produces fly ash and bottom ash, both of which are classified as hazardous waste due to their high alkalinity (they also contain heavy metals). About 45% of the oil shale used in combustion ends up as ash (Gavrilova, 2005). Estonia has introduced fluidised bed combustion in power plants, increasing their efficiency. Despite this effort, levels of ash have increased in recent years (Figure 5.6) due to higher levels of power generation.

The ash has been deposited in landfills that cover about 2 000 ha. The leachate from these ash fields has contaminated soils and groundwater (Gavrilova, 2005). Oil shale ash is used in building materials and in agriculture to reduce the acidity of soils, as well as for the production of mineral fertilisers. Between 2005 and 2014, the oil shale ash recovery grew from 3.3% to 4.8% (MoE, 2015b). While Eesti Energia has researched methods to recycle oil shale ash for road building and in other construction areas (Osamat, 2015), the government is setting only a modest target of 4.5% ash recovery for 2020 in its oil shale NDP (MoE, 2015a).

Semi-coke and other wastes

Three existing refineries located near the oil shale mines generate oil products and gas. Approximately 3 t of hydrocarbon-containing waste, mainly solid semi-coke (containing polycyclic aromatic hydrocarbons) and viscous pitch, are generated for each tonne of shale oil produced. According to the MoE, new filtering methods have reduced the amount of waste pitch produced.

Significant amounts of semi-coke could be used in cement production, thereby replacing natural limestone and oil shale and saving these resources (SEI, 2007), but so far these techniques have not been used. Thus, this waste has also been landfilled, which has led to groundwater contamination in the area (Gavrilova, 2005). Old landfills present a particularly serious pollution legacy. The process of closing and cleaning up the semi-coke landfills of Kohtla-Järve (Box 5.3) and Kiviõli has been almost completed with support from EU structural funds. However, an audit discovered that the quality of preparation of these projects was poor; it resulted in significantly higher costs compared to initial offers submitted by contractors (NAO, 2015). Monitoring of air and water pollution at these and other landfill sites should be continued and improved.

The large landfill at Kohtla-Järve has received waste from the production of oil products since 1938, including ash and semi-coke. The landfill now contains over 80 million t of semi-coke. It has created air pollution, including volatile organic compounds, as well as groundwater pollution. In 1997, ditches were dug around the site to extract leachate, which was sent to a wastewater treatment plant. Nonetheless, significant groundwater contamination from many years of leaching remains.

To meet EU requirements, the Ministry of the Environment decided to close a large section of the landfill. The work, which started in 2010, included reconstructing the drainage ditches and putting a waterproof cap on the closed area. It was financed largely by EU funds. The work was delayed, however, when a large portion of the closed landfill self-ignited. Although the project was largely completed by 2015, independent experts contend that the landfill still emits pollutants to the air and that groundwater contamination continues.

Source: Vallner et al. (2015).

According to NAO (2015), the quality of reported data for hazardous ash and semi-coke arising from oil shale use needs to be improved. The companies in these sectors estimate waste levels, but they use different methods. The MoE should review these methods and establish a common approach.

4.3. Impact on water bodies

The oil shale sector is the largest water consumer of the country. Ida-Viru county, where oil shale deposits are located, accounted for about 95% of all abstracted water in Estonia over the last eight years (Statistics Estonia, 2016). The sector’s water abstraction includes large volumes of surface water used for cooling in oil shale-fired power plants, as well as water pumped out of mines and quarries; the amount depends largely on rainfall (Pihor et al., 2013). The NDP for Oil Shale Use for 2016-30 sets a 2020 target of 14 m3 of groundwater pumped out per tonne of oil shale extracted, which is only slightly below the 2013 average level of 15 m3 (MoE, 2015a).

Mining operations have a considerable impact on the hydrological regime of the Ida‐Viru oil shale basin, influence groundwater infiltration and affect river run-off and flow feed, causing land subsidence. In addition, water discharges from mines affect the chemical composition of surface water and groundwater. High sulphate concentrations in the mine water and its acidity (high pH) have been particularly problematic. Studies also indicate a change in river water temperature and ice conditions due to discharges of warmer mining water (Vaht, 2014).

Due to the impossibility of reaching the good status water quality targets of the Water Framework Directive by 2025, Estonia requested an exemption. It cited the region’s socio-economic conditions – the need to continue mining at present levels – that make it difficult to reduce water pollution (EC, 2012). However, an action plan would be necessary to prevent further deterioration and to protect adjacent groundwater bodies, which are considered at risk (NAO, 2014).

The poor quality of groundwater in the oil shale mining area also has a direct impact on public water supply. Due to exploitation of the upper groundwater levels during mining activities, the bore wells need to access deeper groundwater levels. This implies higher costs of water supply (Gaškov et al., 2012). In addition, a survey by the NAO among local authorities revealed that mining strongly affects the availability and quality of water in wells. These issues are considered problematic even in 55% of the areas where mining has been suspended or mines have been closed. About 70% of local authorities in affected areas reported that some drinking water wells had dried up due to oil shale extraction, and 43% of local authorities signalled the low water quality in some wells (NAO, 2014).

Peat extraction also disrupts water bodies. Estonia has more than 6 000 ha of wetlands with a damaged water ecosystem as a result of peat harvesting during Soviet times. To achieve a good status of water bodies, the natural hydro-morphological water regime must be restored in these areas, thereby creating habitat conditions necessary for recovery of species.

4.4. Impact on air quality

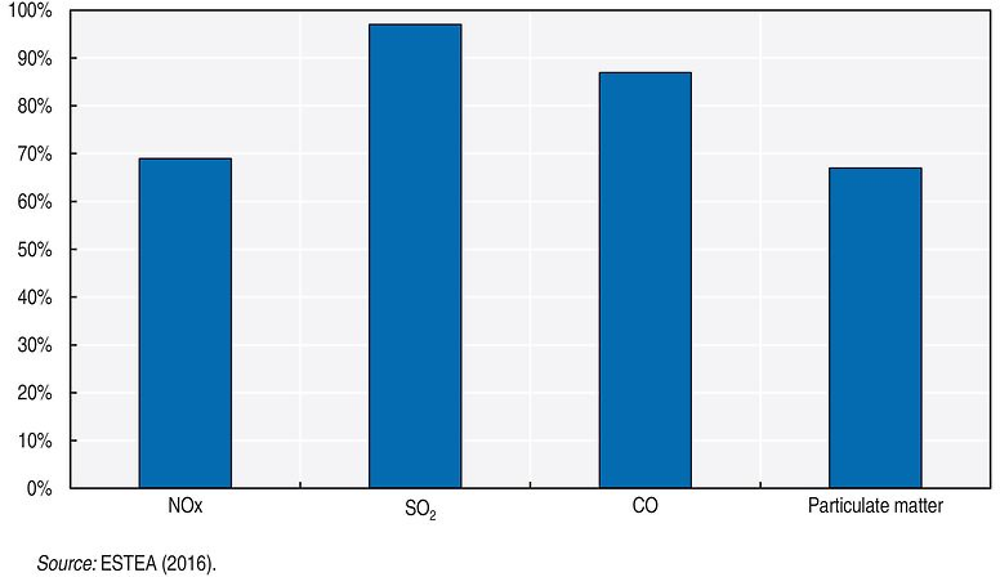

The impact of mining itself on air quality is relatively small. However, air quality issues (SO2, NOx, particulate matter and CO2) associated with oil shale-based electricity and heat production, shale oil production and landfilling of hazardous waste from these processes are significant, particularly in Ida-Viru county (Figure 5.7).

Oil shale combustion to produce electricity or heat, and its heat transformation into shale oil is carbon-intensive. Estonia has the sixth highest level of GHG emissions per capita among OECD member countries (Chapter 1). According to NAO (2014), the amount of CO2 emissions generated per unit of oil shale energy and heat production increased by 11% between 2007 and 2012.

As part of the EU accession requirements, Estonia agreed that emissions from oil shale power plants would not exceed 25 000 tonnes after 2012. Desulphurisation equipment installed at the oil shale-fired Narva power plant in 2012 significantly contributed to the decrease of SO2 emissions (Chapter 1). As a result, Estonia complied with interim emission limit values for SO2 and particulate matter from large combustion plants; the EU had granted these interim limits for a transitional period that ended on 31 December 2015. However, Estonian power plants can comply with the emission limit values imposed by the EU Industrial Emissions Directive (2010/75/EU) as of 1 January 2016 only by curtailing their operations; significant technology investments would be required to reduce unit emissions.

4.5. Health implications of mining

The health implications of mining have not been thoroughly investigated in Estonia. The first study on the health impacts of the oil shale sector was conducted in 2014 by the Estonian Health Board in co-operation with different departments of Tartu University and the Estonian Environmental Research Centre (Orru et al., 2015).

The study indicates the health status of residents of Ida-Viru county is worse in many respects than elsewhere in Estonia, principally due to environmental pollution originating from the oil shale sector. However, this region is characterised by complex problems (such as other forms of industrial pollution, old contaminated sites, a difficult socio-economic situation), which also have an impact on the health of residents (Box 5.4). Further health impact studies are planned under the Oil Shale NDP for 2016-30.

Although the state of the environment has improved significantly over the years, the life expectancy of a child born in Ida-Viru county is still nearly five years shorter than of a child born in southern Estonia or in Tallinn. Most health problems in Ida-Viru are related to air quality. The rates of respiratory system disorders diagnosed in children and the mortality from cardiovascular disorders are also higher in Ida-Viru county than elsewhere in Estonia. In addition, the study showed that the proportion of children with potential risk of asthma is higher in Ida-Viru county than in Lääne-Viru and Tartu counties.

Apart from the living environment, the work environment also affects morbidity levels. People who have worked in the oil shale sector have much more frequently reported symptoms of respiratory diseases, hypertension, stroke, heart diseases and diabetes than those who have not.

Source: Orru et al. (2015).

5. Policy instruments and their effectiveness

Extraction permits and issue-specific environmental permits are the main instruments for regulating environmental impacts of mining activities. The sector’s main regulatory issues are setting of, and monitoring and enforcing compliance with, conditions of such permits, including land restoration requirements.

Environmental taxes are the main economic instrument affecting the mining sector. They are regulated by the Environmental Charges Act (2006)4 and include extraction taxes, air and water pollution taxes, waste disposal taxes, water abstraction taxes, etc. Environmental taxes account for a significant share of operating expenses in the mining and energy sector – 5% in 2011 (Statistics Estonia, 2016). However, they appear to be too low to encourage innovation and investment in cleaner technologies.

5.1. Permits

Beginning in 2008, the Earth’s Crust Act set a maximum limit of oil shale excavation of 20 million t per year to ensure sustainable use of oil shale resources. All four companies with permits have to comply with their share of this total extraction limit. So far, none has exceeded its respective limit.

In 2015, the Earth’s Crust Act was amended to allow holders of extraction permits to extract additional amounts of oil shale as compensation for the years 2009-14 when they did not exceed the established extraction limit. In this way, it intended to give more flexibility to smaller mining companies and reduce Eesti Energia’s monopoly. As the limit was set significantly above actual excavation amounts, such a step would inevitably lead to an increase of the sector’s environmental impacts. At the same time, allowing more competition for oil shale extraction permits may open opportunities for more effective oil shale use. NAO (2015) suggested that the government promote a public debate on the negative impacts of mining and use of oil shale and the future of the oil shale sector. It recommended postponing decisions on new extraction limits and deployment of new excavation areas until such debate has taken place.

The MoE issues permits for the exploration and extraction of mineral resources of national importance (mostly oil shale), although this responsibility is expected to be transferred to the Environmental Board by the new Earth’s Crust Act. The Environmental Board issues exploration and extraction permits for deposits of local importance (construction minerals and peat). In practice, with respect to construction minerals, the issuance of a geological exploration permit often establishes new quarries before assessment of the environmental impact caused by extraction (NAO, 2009).

Oil shale combustion and processing are subject to integrated pollution prevention and control or issue-specific environmental permits for air and water pollution releases and waste management, issued by the Environmental Board (Chapter 2). According to NAO (2015), the Environmental Board has not set sufficiently detailed and comprehensible conditions in environmental permits to regulate how a company should monitor and mitigate the environmental impact of its activities. The Environmental Board has not been using the conditions of environmental permits to influence companies to reduce dumping of oil shale waste and increase waste reuse. Moreover, extraction permits do not include any financial requirements and guarantees to conduct remediation. This might lead to problems in case of bankruptcy of the permit holder when the obligations are transferred to the land owner who is not able to take up the recovery.

The Environmental Board is supposed to collect information about the environmental impact of exploration and mining of natural resources. It should periodically verify whether the company’s claims of extraction volumes correspond to the actual situation and to permit provisions, and whether the company is mining the deposit as required. If serious problems arise in the course of mining operations or if the company fails to meet the requirements, the Environmental Board has a right to review, amend or withdraw its permit.

However, NAO (2015) stated that there is inadequate compliance monitoring of waste management in oil shale mining and processing, and company-reported data are not sufficiently checked either by the Environmental Board or by the Environmental Inspectorate. The NAO has identified several errors in waste reporting that a reporting control system could easily have identified. The same report (NAO, 2015) alleges that the MoE has failed to consolidate all the relevant environment monitoring data, including those collected by companies, into an integrated information system. This makes it difficult to analyse and use data on the sector’s environmental impact.

5.2. Land restoration requirements

The Earth’s Crust Act and the subsequent 2005 regulation of the Ministry of the Environment require restoration of land affected by mining sites. According to this regulation, the extraction permit holder is required to remediate land used for mining of mineral resources through a restoration project. The project should describe technical and environmental aspects of land restoration and must be approved by the Environmental Board.

Remediating mined areas into useable land depends on the mining technology and the type of mined resource. In the case of open-cast mining, a major concern is restoring the productivity of the land; conversely, underground mining may lead to land subsidence and requires restoration of the groundwater regime. Soviet-era areas of land subsidence have been investigated and refilling has been done where needed. However, the risk of further subsidence remains. Old site plans and reports are incomplete and sometimes misleading, which may result in unexpected land subsidence in old mining areas (Baltic Countries Mineral Industry Handbook, 2015).

Landscapes disturbed through mining must be remediated so that they blend in with the surrounding area and are fit for reuse. This way, for example, an old open-cast mine can be afforested or transformed into a field or lake, or redeveloped entirely as a residential or recreational area. Research has shown that if land reclamation activities are planned skilfully, mining areas could be turned into valuable forests, commercial zones or even agricultural land (Kaar and Kiviste, 2010).

According to mining permit holders’ reports, the extent of restored areas of oil shale mines reached about 13 000 ha in 2012 (Pihor et al., 2013). The Ahtme and Kohtla mines are excellent examples of effective remediation of open-cast waste deposits into multipurpose recreational areas. These projects, supported with EU funds, have contributed to the tourism potential of north-eastern Estonia.

There are concerns with the restoration of construction mineral quarry sites. The law stipulates the quarry must be reconditioned by the time the extraction permit expires, but these requirements are usually not followed. Extractors commonly apply to extend their extraction permits and expand the quarries before their permits expire; once permits have been extended, the deadline for reconditioning is postponed (NAO, 2009).

5.3. Economic instruments

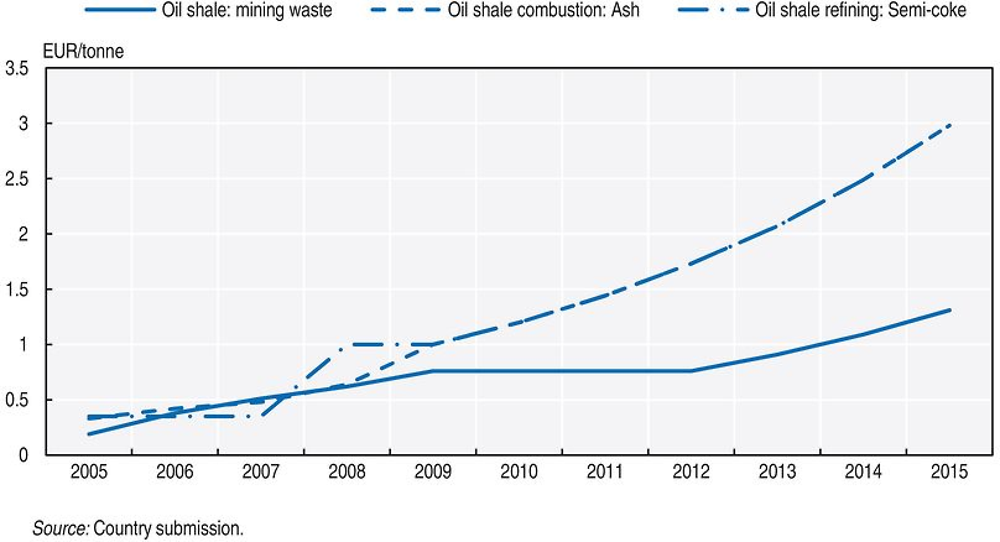

Extraction permit holders pay the mineral resource extraction tax for extraction and use of mineral resources belonging to the Estonian state. These taxes have grown significantly since 2005 (e.g. about three-fold for oil shale), but are not set in relation to the value of the resource (Chapter 3).

Amendments to the Environmental Charges Act (adopted in June 2016) tie extraction taxes for oil shale to the oil price retroactively from July 2015. There is a fixed minimum extraction tax of EUR 0.275 per tonne that corresponds to “compensation for environmental distress in the area”; revenues from the tax revert to the local government. Above this fixed amount, the variable tax depends on the oil price. In 2016, the extraction tax is set at its minimum until the end of 2017 (when a new extraction tax calculation methodology is expected to be approved); this effectively cuts the rate by more than 5.7 times. The government is reducing the tax burden on the oil shale industry to increase the profitability of investment in shale oil production in the context of low global oil prices. However, this tax break deprives the government of significant environmental tax revenues and runs contrary to its green tax reform agenda.

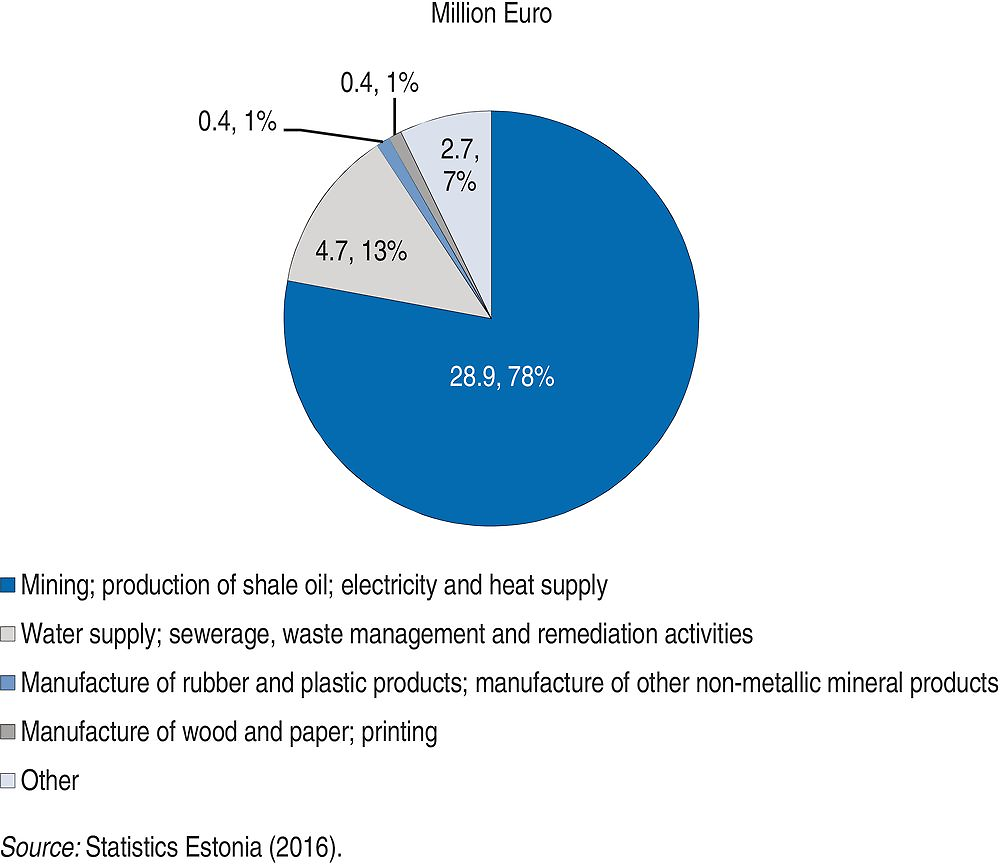

There are also taxes on air and water pollution, as well as waste disposal (Chapter 3). The largest share (almost 80%) of pollution taxes is paid by enterprises active in mining, production of shale oil, electricity and heat supply (Figure 5.8).

Environmental taxes increased steadily between 2005 and 2015 (Chapter 3). For example, waste disposal taxes rose seven-fold for non-hazardous mining waste and more than eight-fold for oil shale ash and semi-coke (Figure 5.9). However, a study concluded the impact of these taxes on the volume of pollution releases is unclear (Lahtvee et al., 2013). Air emissions and wastewater discharges have been reduced, but more due to investments made to comply with stricter EU environmental standards than in response to an economic incentive. Waste disposal charges may have affected waste recovery practices: Eesti Energia Kaevandused has constructed several crushed stone production plants and recovered as much as 70% of its non-hazardous mining waste in 2010-11, compared to 20% in previous years (ESTEA, 2014). Still, this remarkable increase in the waste recovery rates could be attributed primarily to strong commercial demand for construction materials in those years.

The taxes’ environmental effectiveness appears to be further compromised by lack of enforcement of their payment. While the Environmental Board is supposed to monitor payment of environmental taxes, it recently reported to the NAO that it had not carried out such supervision since 2011. As a result, it is unclear whether the state received the right amount of tax revenue (NAO, 2014).

In general, businesses perceive environmental taxes as a source of revenues for the government rather than as an incentive to reduce environmental impacts (NAO, 2014). For environmental taxes to stimulate introduction of cleaner technologies, tax rates should be increased for priority pollutants and landfill disposal of mining waste (Chapter 3), and their collection closely monitored.

This would require overcoming the industry’s significant resistance to environmental tax rate increases. Eesti Energia and the sector’s other companies evoke financial difficulties caused by low world oil prices. In response to this pressure, in the first half of 2016, the MoE proposed amendments to the Environmental Charges Act to reschedule payment of taxes on landfill disposal of oil shale mining, combustion and processing waste. Like the above-mentioned proposal to lower extraction taxes, this action would undermine both the environmental incentive and revenue-raising effect of economic instruments in the oil shale sector and amount to an environmentally harmful subsidy (Chapter 3).

-

Align the policy of oil shale extraction limits with the sector’s overall efficiency and environmental goals stated in relevant strategic documents; make the NDP’s efficiency and environmental targets for 2025 and 2030 more ambitious in view of reducing the share of oil shale in the energy mix, and plan measures for achieving them; strengthen the information base on the sector’s environmental and health impacts, including through establishing standard monitoring and reporting procedures and more diligent verification of companies’ self-reporting data by the Environmental Inspectorate.

-

Encourage deployment of more efficient oil shale mining and processing technologies; develop partnerships between government and industry to facilitate cost-effective transition to cleaner and more efficient oil shale extraction and use; develop a reference document on best available techniques in energy generation and oil production and rational use of extracted resources.

-

Consider additional actions towards the diversification of the Ida-Viru region’s economy away from oil shale mining and use, envisaging measures to mitigate the potential social impacts (e.g. improving labour mobility and training) through active collaboration between the central government, municipalities, employers and trade unions.

-

Reinforce efforts to increase the recovery of mining waste, including ash and semi-coke from oil shale processing, by investing in research and development in collaboration between the government, research institutions and enterprises; consider increasing landfill disposal taxes for oil shale mining and processing waste; improve the monitoring of air and water pollution in mining areas.

-

Strengthen the permitting regime for the mining industry by ensuring that extraction and environmental permits contain clear conditions for waste minimisation and post-operation land remediation; better enforce land restoration requirements, particularly for construction minerals mining sites; provide financial support for innovative land restoration projects.

References

All, T. (2014), Põlevkivi kaevandamise ja kasutamise kumulatiivne mõju loodus- ja elukeskkonnale ning selle indikaatorid [Cumulative Impact of Oil Shale Mining and Use on Natural and Living Environment and Indicators for Measuring It], World Energy Council Estonia, www.energiatalgud.ee/img_auth.php/8/84/WEC_Eesti._P%C3%B5levkivitoostuse_kumulatiivne_m%C3%B5ju.pdf (accessed 8 November 2015).

Baltic Countries Mineral Industry Handbook (2015), Volume 1: Strategic Information and Regulations, World Business and Investment Library, International Business Publications, Washington, DC.

Batkhuyag, S. and G. Yondongombo (2012), “What are shale oil, shale gas and oil shale?”, Mongolian Mining Journal, 24 September 2012, Journalism for Development, Ulaanbaatar, http://en.mongolian miningjournal.com/content/34622.shtml.

EASAC (2007), A Study on the EU Oil Shale Industry – Viewed in Light of the Estonian Experience, Report to the Committee on Industry, Research and Energy of the European Parliament, European Academies Science Advisory Council, Halle, www.easac.eu/fileadmin/PDF_s/reports_statements/Study.pdf.

EC (2012), Commission Staff Working Document, Member State: Estonia, Report from the Commission to the European Parliament and the Council on the Implementation of the Water Framework Directive (2006/60/EC): River Basin Management Plans, European Commission, Brussels, http://ec.europa.eu/environment/water/water-framework/pdf/3rd_report/CWD-2012-379_EN-Vol3_EE.pdf.

Eesti Energia (2016), “Eesti Energia earned a net profit of EUR 40 million last year”, Press Release, 25 February 2016, www.energia.ee/en/uudised/-/news/2016/02/25/eesti-energia-teenis-moodunud-aastal-40-miljonit-eurot-puhaskasumit.

Eesti Turbaliit (2016), Estonian Peat Association website, www.turbaliit.ee (accessed 19 May 2016).

Ernst and Young (2014), Estonian Oil Shale Mining and Oil Production: Macroeconomic Impacts Study, 23 May 2014, Ernst and Young Baltic, Tallinn, www.energiatalgud.ee/img_auth.php/6/64/EY._Estonian_oil_ shale_mining_and_oil_production_macroeconomic_impacts_study.pdf.

ESTEA (2016), Õhku paisatud saasteainete heitkogused Eestis [Greenhouse Gas Emissions of Estonia], Estonian Environment Agency, Tallinn, www.keskkonnaagentuur.ee/et/saasteheitkogused.

ESTEA (2014), Estonian Environmental Review 2013, Estonian Environment Agency, Tallinn, www.keskkonnaagentuur.ee/et/review201.

Eurostat (2015), Environmental Data Centre on Waste (database), http://ec.europa.eu/eurostat/web/waste (accessed 14 December 2015).

Federal Reserve Bank of St. Louis (2016), Crude Oil Prices: Brent – Europe (database), https://research.stlouisfed.org/fred2/series/DCOILBRENTEU/downloaddata (accessed 3 February 2016).

Galgóczi, B. (2014), “The long and winding road from black to green: Decades of structural change in the Ruhr region”, International Journal of Labour Research, Vol. 6/2, International Labour Organization, Geneva, pp. 217-240, www.ilo.org/wcmsp5/groups/public/---ed_dialogue/---actrav/documents/publication/wcms_375223.pdf.

Gaškov A. et al. (2012), Põlevkivi kasutamise riikliku arengukava 2016-30 koostamiseks vajalike andmete analüüs [Data Analysis for the Preparation of the National Development Plan of the Oil Shale Use for 2016-30], OÜ Inseneribüroo STEIGER, SA Säästva Eesti Instituut, AS Maves, OÜ Baltic Energy Partners, Tallinn, www.seit.ee/file_dl.php?file_id=213.

Gavrilova, O. et al. (2005), Life Cycle Analysis of the Estonian Oil Shale Industry, Estonian Fund for Nature and Tallinn University of Technology, Tallinn, www.nommeteeselts.ee/attachments/082_life_cycle_ analysis_of_oil_shale_industry_of_estonia_03_12_05_ff.pdf.

IEA (2016a), World Energy Statistics and Balances (database), http://stats.oecd.org/Index.aspx?DataSetCode= WBAL (accessed 15 May 2016).

IEA (2016b), Energy Technology Research and Development (database), http://stats.oecd.org/Index.aspx?Data SetCode=BUDGET_RDD (accessed 15 May 2016).

IEA (2013), Energy Policies Beyond IEA Countries: Estonia 2013, IEA/OECD Publishing, Paris, https://doi.org/10.1787/9789264190801-en.

Kaar, E. and K. Kiviste (2010), Maavarade kaevandamine ja puistangute rekultiveerimine Eestis [Mineral Mining and Heap Re-cultivation in Estonia], Estonian University of Life Sciences, Tartu, http://erb.nlib.ee/? kid=26255327.

Karofeld, E. (2004), “Mud-bottom hollows: Exceptional features in carbon-accumulating bogs?”, The Holocene, Vol. 14/1, Sage Journals, pp. 119-124, http://hol.sagepub.com/content/14/1/119.full.pdf.

Karu, V. et al. (2008), “Future of oil shale mining technology in Estonia”, Oil Shale, Vol. 25/2 Special, Estonian Academy Publishers, Tallinn, pp. 125-134, www.kirj.ee/public/oilshale_pdf/2008/issue_2S/oil-2008-2S-4.pdf.

Kearns, J. (2015), Trends in Estonian Oil Shale Utilization, International Centre for Defence and Security, Tallinn, October 2015, www.icds.ee/fileadmin/media/icds.ee/failid/Jordan_Kearns_-_Trends_in_Estonian_ Oil_Shale_Utilization_Oct_2015.pdf.

Lahtvee, V. et al. (2013), Keskkonnatasude mõjuanalüüs [Impact Analysis of Environmental Charges], SEI Tallinn and Tartu University, www.seit.ee/publications/4447.pdf.

MoE (2015a), Põlevkivi kasutamise riiklik arengukava 2016-30 [National Development Plan for Oil Shale Use 2016-30], Ministry of the Environment, Tallinn, www.envir.ee/sites/default/files/arengukava_ eelnou.pdf.

MoE (2015b), Response to the Questionnaire for the OECD Environmental Performance Review of Estonia, Ministry of the Environment, Tallinn.

MoE (2014), Eesti keskkonnategevuskava aastateks 2007–2013, lõpparuanne [Environmental Action Plan of Estonia for 2007-13, Final Implementation Report], Ministry of the Environment, Tallinn, www.envir.ee/sites/default/files/ktk_2007-2013_lopparuanne.pdf.

MoE (2010), Eesti turbaalade kaitse ja säästliku kasutamise alused: Eelnõu [Protection of Estonian Peatlands and Principles of Sustainable Use: Draft], Ministry of the Environment, Tallinn, www.envir.ee/sites/default/files/turbakontseptsioon_kodulehele_taiendatud.pdf.

MoE (2008), National Development Plan for the Utilization of Oil Shale 2008-15, Ministry of the Environment, Tallinn, www.envir.ee/sites/default/files/polevkivi_kasutamise_arengukava_2008_2015_eng.pdf.

MoE (2006-14), Eesti Vabariigi maavaravaru koondbilansid [Aggregated Balance Sheets of Estonian Mineral Resources], Ministry of the Environment, Tallinn, www.envir.ee/et/eesti-vabariigi-maavaravaru-koondbilansid.

NAO (2015), Government Actions in the Organisation of Oil Shale Mining and Processing Waste Management, National Audit Office of Estonia, Tallinn, 20 May 2015, www.riigikontroll.ee/tabid/206/Audit/2350/Area/15/language/en-US/Default.aspx.

NAO (2014), Actions of the State in Directing the Use of Oil Shale, National Audit Office of Estonia, Tallinn, 19 November 2014, www.riigikontroll.ee/tabid/206/Audit/2314/Area/15/language/en-US/Default.aspx.

NAO (2009), National Arrangement of Mining Mineral Resources Used in Construction, National Audit Office of Estonia, Tallinn, 14 May 2009, www.riigikontroll.ee/tabid/206/Audit/2091/Area/15/language/en-US/Default.aspx.

Orru, H. et al. (2015), Põlevkivisektori tervisemõjude uuring [Study of the Health Impact of Oil Shale Sector], University of Tartu, www.terviseamet.ee/info/projektid/polevkivisektori-tervisemojude-uuring.html.

Osamat (2015), “Project Overview” and other web pages, EU LIFE+ Project, www.osamat.ee/en (accessed 17 November 2015).

Pihor, K. et al. (2013), Põlevkivi kaevandamise ja töötlemise sotsiaalmajanduslike mõjude analüüs [Socio-economic Impact Analysis of Oil Shale Mining and Processing], Praxis Center for Policy Studies, Tallinn, www.praxis.ee/tood/polevkivi-kaevandamise-ja-tootlemise-sotsiaalmajanduslike-mojude-hindamine.

Rail Baltica (2016), Project Description, website, www.rail-baltica.com (accessed 3 April 2016).

Rell, M. and M. Kupts (2014), Põlevkivitööstuse mõju demograafilistele arengutele kuni aastani 2030 [Impact of the Oil Shale Industry on Demographic Trends up to 2030], Praxis Center for Policy Studies, Tallinn, www.praxis.ee/wp-content/uploads/2014/09/Põlevkivitööstus-ja-demograafia.pdf.

SEI (2007), Jäätmete saastetasu rakendamise analüüs, uued suunad ja ettepanek uute tasumäärade rakendamiseks aastatel 2010-15 [Analysis of Pollution Charges on Waste, New Directions and Proposal for New Charge Levels for 2010-15], Stockholm Environment Institute, Tallinn, www.envir.ee/sites/default/files/elfinder/article_files/jaatme_aruanne23_04_08_0.pdf.

Statistics Estonia (2016), Statistical Database, http://pub.stat.ee/px-web.2001/dialog/statfile1.asp (accessed 7 May 2016).

Statistics Estonia (2015), Statistical Yearbook of Estonia, Statistics Estonia, Tallinn.

Tohver, T. (2011), Põlevkivi kaevandamis- ja rikastamisjääkide kasutamine [Utilization of Waste Rock from Oil Shale Mining], Doctoral thesis, Tallinn University of Technology, http://digi.lib.ttu.ee/i/?583.

Vaht, R. (2014), The Impact of Oil Shale Mine Water on Hydrological Pathways and Regime in north-east Estonia, Doctoral thesis, University of Tartu, 5 November 2014, http://hdl.handle.net/10062/44113.

Valgma, I. et al. (2012), Sustainable Mining Conditions in Estonia, Tallinn University of Technology, www.ene.ttu.ee/maeinstituut/artiklid/2012/Valgma_Leiaru_Karu_Isk%C3%BCl_Sustainable_mining_ conditions_in_Estonia.pdf.

Valgma, I. (2001), Map of the Baltic Oil Shale Area, www.ene.ttu.ee/maeinstituut/poster/rez.html (accessed 20 May 2016).

Vallner, L. et al. (2015), “Environmental risks and problems of the optimal management of an oil shale semi-coke and ash landfill in Kohtla-Järve, Estonia”, Science of the Total Environment, Vol. 524-525, 15 August 2015, Elsevier, Amsterdam, pp. 400-415, https://doi.org/10.1016/j.scitotenv.2015.03.130.

Virkus, R. (2014) Võimalused Aidu karjääri taaskasutuseks ja Uus-Kiviõli põlevkivikaevanduse integreerimiseks keskkonda [Reclamation Possibilities of Aidu Open-cast Quarry and Environmental Design Approach of Uus-Kiviõli Mine], Master’s thesis, Estonian University of Life Sciences, http://dspace.emu.ee/xmlui/handle/10492/1657.

Notes

← 1. The targets for 2025 and 2030 are either the same as for 2020 or remain to be specified.

← 2. The Geological Survey of Estonia reports the extraction of pure oil shale, while Statistics Estonia reports the consumption of “trade oil shale” (containing limestone and other impurities, which increase the volume). This explains the apparent discrepancy between the extraction levels of 15 million tonnes and the use data in Figure 5.2.

← 3. In the absence of a BAT reference document for oil shale processing, Estonian power plants have to comply with emission limit values for lignite-based power generation under the EU Industrial Emissions Directive.

← 4. Estonia’s Environmental Charges Act refers to resource and pollution taxes as “charges”, but the OECD defines them as taxes, and they are referred to as such in this report.